Bearings Of Surface Grinding Motor

Thrust Bearing Failure

· Overloading of the thrust bearing. Surface Finish. Crankshaft thrust faces are difficult to grind because they are done using the side of the grinding wheel. Grinding marks left on the crankshaft face produce a visual swirl or sunburst pattern with scratches, sometimes crisscrossing one another in a crosshatch pattern similar to honing marks on a cylinder wall. If these grinding marks are not ...

Shaft Machining_Technology, Material, Tolerance ...

For shafts fitted with P0class precision bearings, the tolerance class is generally IT6, and the housing bore is generally IT7. For appliions with high requirements for rotational accuracy and smoothness of operation (eg, motors, etc.), the shaft should be IT5 and the housing bore should be IT6. Structural classifiion The structural design of the shaft is an important step for the ...

bearings of surface grinding motor

bearings of surface grinding motor. MAHLE Aftermarket North America | Installation Tips. The surface lay generated by grinding would cause abrasion to the bearing surfaces if left unpolished. By polishing in the direction shown in either the figure 3 or 4, the surface lay is reversed by the polishing operation removing fuzz created by grinding and leaving a surface lay which will not abrade ...

Main Bearing Failure Modes

· Main Bearing Failure Modes. The simplest way to identify the failure mode of a bearing is to examine the sleeve surface and characterize how the material itself failed. Each failure mode can have several different root causes that lead to the eventual failure of the bearing surface. The most common failure modes observed in engine main bearings ...

Race (bearing)

Whilst grinding, the bearing cases run through the grinding stages in one long tube of casings that is showered with a cutting fluid. The 'tube' rests on a hardened steel blade with an angled, highly ground surface held on a horizontal plane between the grinding wheel and regulating wheel, often named a Work Rest Blade, the tube causes wear on the working surface of the blade so it must be ...

Do you have to machine the crankshaft after a spun main ...

I had a spun main bearing due to low oil, the crankshaft journal is pretty scratched, no dents just looks spun on the surface. To the inexperienced diyer it's hard to imagine this would be a huge issue if you put on a new bearing yet everything I read says that any markings on the journal will ruin your replacement bearing asap, I think I have that correct.

Grinding – DC Brewer Machinery

Hydrostatic Bearing Series (H Series) RC18H | C20H Hydrostatic Bearing Series (H series) Hydrostatic bearings of the grinding spindle are surrounded by high pressure oil film, eliminating metaltometal contact, overheating, oil leakage since no oil seals are utilized, providing less power consumption, high rigidity and high vibration damping performance.

bearings of surface grinding motor

Type 51 Heavy Duty Knife Surface Grinder 10" Grinding Wheel to 12 HP Precision Grinding Motor 1800 RPM 40" to 500" Grinding Length with 6" or 7 ... SB1023 6" x 12" Surface Grinder ® Home

HighSpeed Motor Spindles | CNC Grinding Milling Spindles

Grinding spindles are available in sizes 6030 mm, with a speed range of 3,000 to 60,000 RPM, and motor power up to 25 kW. LPR Global's spindles are widely used by grinding machine manufacturers for cylindrical grinding, ID/OD grinding, surface grinding and tool grinding. Appliions include grinding bearings, collets, wheel dressers, quartz ...

Home

Surface grinding machine M7140 is used to produce a smooth finish on flat surfaces. Applicable to all kinds. Surface Grinding Machine – SGA3063 . Surface Grinding Machine – SGA3063 The welldesigned structure have good rigidity and keeps the machine with high accuracy. Cylinder Honing Machine – 3MB9808. The machine 3MB9808 is mainly used for honing engine cylinder of automobiles motor ...

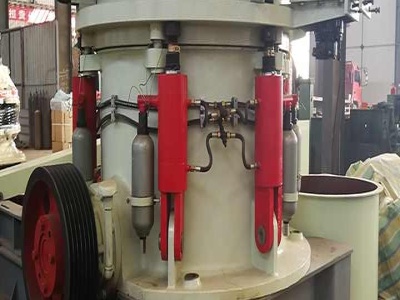

Grinding Mill Gear Assembly

· Grinding Mill Gear Assembly. We will begin with the mill's bull gear assembly and work towards the motor, The BULL GEAR, sometimes called the RING GEAR is designed to turn the mill transforming the energy of the motor into motion for the mill. By mill we refer to .

Grinding, polishing and glazing of the occlusal surface do ...

· Grinding introduces surface defects and increases roughness of FSZ ceramics. • Polishing and glaze lead to the surface smoothening effect (decrease defects and reduce roughness). • No phase transformation was observed (only cubic and tetragonal phases detected). • No deleterious effect on the mechanical fatigue performance was observed. • All cracks started on the bonding surface ...

Plain bearing surface grinder

· I bought my BS No. 2 surface grinder in 1979. It was built in 1929. This was the model with a big old motor in the base and a very long leather belt to drive the plain bearing spindle, using many idler pulleys. Weight is around 1000 pounds. I scraped and totally disassembled and rebuilt it.

Precision Grinding | OD Grinding|ID Grinding|ID Honing|ID ...

Grinding (Inner Diameter), "Internal Grinding", is a method of grinding the inside diameter of a part's cylindrical opening to the exact size and surface finish. Example parts can be rollers, bearings, tubing, bushings and more. We have the following Grinding Capabilities: • .

Bearing | Noritake Abrasives

The high quality surface finish of the bearing is provided by the Noritake Super Finishing Stones which are applied to inner and outer ring of the bearing. From Roller Bearing to Tapper Roller Bearing Noritake grinding wheels feature extraordinary quality abrasives and creative technology for producing high quality antifriction bearings. The Noritake Flatdy is a disc grinding wheel with a new ...

Horizontal Rotary Surface Grinder :: HR200AND Model ...

Precision grinding machine. Surface finishing to mirror class. Automatic Trim Compensation. On line spindle vibration monitor. Machine base fully supported design creating high rigidity structure. Y, Z axis and rotary driven by AC servo motor. Coolant system. Magnetic filter. Auto. paper strip filter with magnetic separator and coolant system.

GRINDING PROCESS

bearing races, bushings, and many other parts, Assistant Professor, Department of Mechanical Engineering, BSACIST, Chennai 48 . Centre less grinding machine It is used to grind curved surface work piece which are long and slender. Work piece rests on a workrest blade and is backed by a second wheel called as regulating wheel. Grinding wheel pushes the work piece down .

DIY Surface Grinder For Making Precision Parts At Home ...

· One set of surface grinder bearings could buy a container of angle grinders. This pile of trash is closer to a belt sander than a surface grinder. .

Surface Grinding Machine

Maximum Grinding Surface. 300 mm x 600 mm. Table Speed. 5 25 m/min. Wheel Speed. 3500 rpm. Features : Optimized Structure The major parts of Perfect grinders are manufactured from high quality cast iron combined with an outstanding structural design. Major parts are stress relieved to ensure maximum rigidity, stability and machining accuracy.

Processing of bearing rings, round and excentric workpieces

CYLINDRICAL GRINDING OF STATORS, BEARINGS, GEARS The Vertical Rotary Table Grinder Model TRIREX is a modular designed machine. The Vertical Rotary Table Grinder has a bigger vertical stroke, which allow the machine to process the required working envelope without having an adjustable rail or a compound slide. The Vertical Rotary Table Grinder consists of well proved modules. A long .

How to Use a Surface Grinder Machine

The utility grinding machine consists of a horizontally mounted motor with a grinding abrasive wheel attached to each end of the motor shaft. The electricmotordriven machine is simple and common. It may be benchmounted or floormounted. Generally, the condition and design of the shaft bearings as well as the motor rating determine the wheel size capacity of the machine. Suitable wheel ...

Latest Posts

- موبايل حفلة سحق الأعمال

- تصميم مصنع إعادة التدوير

- برنامج تشغيل كسارة الفك

- سعر خام البورون محطم لفة

- توريد كسارات الفك

- أين يمكنني شراء معدات الطحن

- مخطط 600x900 كسارة الفك

- الصين معدات الصنفرة

- نموذج من كسارة الفك

- مولينو تأثير محطم

- بيع الصين كتلة خرسانية محطم

- شراء ألمانيا الفلسبار مطحنة الكرة

- شريط الذهب محطم

- الرمل الاصطناعي تقرير تكلفة المشروع

- Marble Primary Crusher For Sale

- For Sale For Ball Mills

- Husqvarna Model Bks E

- End Mill Geometry Tables

- Cement Grinding Media Production

- Vertimill Grinding Lineup

- Industry Profile In Elgi Ultra Wet Grinder

- Bearing For Oil Palm Mill

- Grinding Media Balls Suppliers In Indonesia

- Grinding Attachment For Watchmaker S Precision Lathe

- To Buy Stone Crusher

- Superfine Raymond Mill Powder Machine

- Gold Procting Pro

- Pulverizer Pulverizer River Sand Screening Machine

- Super Thermal Power Plant Internship Report

- Crusher In Bharuc In Jodhpur