Between Wet Ball Mill

Wet vs Dry Grinding

· Hope I'm posting in the correct area. I would like to know what the advantages of wet grinding compared to dry grinding are (if any). Would one expect wet ground material to exhibit different leaching characteristics from dry ground materials, even when particle size distributions are identical? I'm dealing with uranium ores in a lab scale ball mill (Bond Ball Mill).

Wet Ball Mill Of Refractories Industries

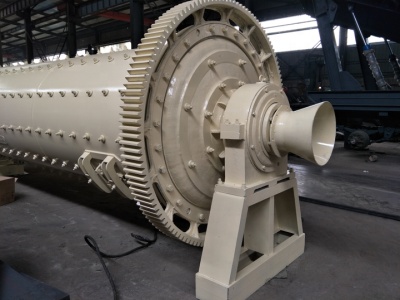

What is the difference between a wet ball mill and a dry. Wet ball mill refers to grinding raw materials after humidifiion mainly used in mineral processing chemical and ceramic industries the main working principle of wet ball mill is that the motor drives the cylinder to rotate through the deceleration device and the crushed ore .

Mills » Products » CEMTEC

Ball mills for wet and dry grinding appliions CEMTEC offers grinding solutions with ball or pebble mills for wet or dry appliions with an open or a closed grinding circuit. The mills are available with either a slide, slide shoe, or spherical rol ler bea ri ng, as well as with either gear rim/pinion, direct, or central drive; they can ...

difference between dry and wet ball mill

Difference between dry and wet ball mill wet milling of cereal grains naldcNalUsdaGovsome of the larger wetmilling plants are equipped with grain driers to dry highmoisture grain corn with a mois ture content under percent can usu ally be stored safely during the winter, but corn that contains more than percent moisture is . difference between wet and dry ball mill. Wet ball milling vs dry ...

Ball Mill For Wet Mill

Wet process ball mill. 25 Wet process ball mill Feeding size ≤25mm Motor Power 18 5800kw Wet process ball mill is widely used in powdermaking production line including cement silie newtype building material refractory material fertilizer ore dressing of ferrous metal and nonferrous metal glass ceramics etc Main bearing adopts large diameter double biserial roller bearing which reduces ...

Properties of cellulose nanofibril produced from wet ball ...

The ball milling was carried out for,,,, and h at room temperature in order to investigate the effect of ball milling time on the production of CNF. To prevent overheating of the cellulose, 10 min of interval was provided between every 5 min of milling. The preparation process is shown in Fig. 1b. The CNF produced from wet ball milling were marked as CNFB.

Overflow VS Grate Discharge Ball or Mill

· Grate Discharge Ball Mill Capacities. The above tables list some of the most common Grate Discharge Ball Mill sizes. Capacities are based on medium hard ore with mill operating in closed circuit under wet grinding conditions at speeds indied. For dry grinding, speeds are reduced and capacities drop between 30% to 50% . Grate Discharge Ball Mill Arrangement Dimensions. The .

The Mechanism and Grinding Limit of Planetary Ball Millingt

the planetary ball mill consists of compressive, abrasive and shear stress of the balls, which is believed to be effective in producing very fine particles. About thirty percent of ball filling of the mill was found to be the optimum. This was explained by an analysis of the motion of the balls and the measurement of the contact force. It was found that the grinding limit is greatly dependent ...

Types Of Wet Ball Mill Machine

Rock wet ball mill plantused economical industries rotary drum type washer screen beneficiation process for manganese in zaire durable but not expensive mining machine ball mill and milling of india high quality air classifier for sodium carbonate circular rocking vibrating screen sudan the function of various quarry plant includes wet ball mills HOME 37. [ Wet Ball Mill Machine Smill Type ...

difference between raw mill and ball mill

difference of vertical raw mill and ball mill. The difference between vertical mill and ball mill 3 Vertical mill allows large air flow so the drying capacity is high The material in the mill is in a suspended state increasing the contact area of materials and airflow When the ball mill grinds the wet raw material it is usually necessary to install additional drying equipment in front of the ...

Ball Mills

· Difference Between Ball Mill and Rod Mill Rod Mills. The principal field of rod mill usage is the preparation of products in the 5 mm— mm (4 mesh to 35 mesh) range. It may sometimes be recommended also for finer grinding. Within these limits a rod mill is usually superior to and more efficient than a ball mill. The basic principle for rod grinding is reduction by line contact between rods ...

Size reduction

Ball mills (wet) Ball mills, as described above, are also a machine of choice for milling solids in wet phase. The design applied here is mainly a ball mill with an agitator, the movement of the agitator making the beads move and impact or friction the particles to be milled.

narrow product size distribution from rod mills is partly ...

Ball mills have a large field of appliion for wet grinding in closed circuit with size classifiers, which also perform advantageously when wet. Dry Ball Milling In fine dry grinding, surface forces come into action, causing cushioning and ball coating, resulting in a less efficient use of energy.

What Are the Feeding Methods of Wet Ball Mill Machine? And ...

The differences between dry ball mill and wet ball mill mainly reflected in three aspects: first, different working principles; Second, different equipment structure; Three, different appliion. Xinhai Mining. Grinding Mill. Similar ideas popular now. Force. Force And Motion. Physics. STEM Challenge.

BLASTING TECHNICAL INFORMATION

Ft Tight Mill Scale 140 Sq. Ft. at 90 PSI Pitted Paint 85 Sq. Ft. Layered Paint 70 Sq. Ft. NO 2 NEAR WHITE BLAST SSPCSP10 #7 NOZZLE Approx. Sq. Ft. Cleaning Per Hour Loose Mill Scale 180 Sq. Ft. Tight Mill Scale 146 Sq. Ft. at 90 PSI Pitted Paint 90 Sq. Ft. Layered Paint 72 Sq. Ft. NO 3 COMMERCIAL BLAST SSPCSP6 #7 NOZZLE Approx. Sq. Ft. Cleaning Per Hour Loose Mill Scale .

Planetary Ball Mill PM 100

Planetary Ball Mills are used wherever the highest degree of fineness is addition to wellproven mixing and size reduction processes, these mills also meet all technical requirements for colloidal grinding and provide the energy input necessary for mechanical extremely high centrifugal forces of a planetary ball mill result in very high pulverization energy and ...

Difference Between Ball Mill

201046Whats the difference between Ball Mill and Raymond Mill Mill materials is being broken, further crush the key equipment. Mill widely used in cement, Portland products, new building materials, refractories, fertilizers, as well as black and nonferrous metal processing industries such as the production of glass ceramics, various ores and other materials may be grinding of dry or wet ...

Dry Grinding VS Wet Grinding

· A slight difference of condition between the two cases, however, is that with dry milling the fluid (air) fills the whole of the mill shell not occupied by the balls, whereas with wet milling the liquid occupies only a part of the mill volume not occupied by the solid charge. This difference would be expected to have some slight effect on the motion of the ball charge but the effect would be ...

Understanding the mechanisms of cooperative physico ...

Oct 31, 2017 · For modelling of wetmilling behaviour, after treatment, the total contents of the reactor vials were transferred without washing to ballmill vessels. For microscopy investigations, cut stem sections of straw, Miscanthus and willow were hydrothermally treated in the microwave reactor at 200 °C in excess water, and the treated samples were ...

Corn Milling: Wet vs. Dry Milling

Corn wet milling and dry milling are the predominant methods of processing and each method produces distinct coproducts. The Corn WetMilling Process. The Corn wetmilling process is designed to extract the highest use and value from each component of the corn kernel. The process begins with the corn kernels being soaked in large tanks called steep tanks in a dilute aqueous sulfur dioxide ...

Ethanol Production

While dry milling is less capital intensive, it also yields less ethanol per bushel of corn than wet milling (Rajagopalan, et al., 2005). Wet milling involves steeping the corn for up to 48 hours to assist in separating the parts of the corn kernel. Processing the slurry separates the germ from the rest of the kernel, which is processed further to separate the fiber, starch, and gluten. The ...

Size reduction

Ball mills (wet) Ball mills, as described above, are also a machine of choice for milling solids in wet phase. The design applied here is mainly a ball mill with an agitator, the movement of the agitator making the beads move and impact or friction the particles to be milled. Design using a loose reduction media can be found, mainly in long horizontal mills but other designs, more efficient ...

Ball Mills

Most ball mills operate most efficiently between 65% and 75% of their critical speed. Photo of a 10 Ft diameter by 32 Ft long ball mill in a Cement Plant. Photo of a series of ball mills in a Copper Plant, grinding the ore for flotation. Image of cut away ball mill, showing material flow through typical ball mill. Flash viedo of Jar Drive and Batch Ball Mill grinding ore for testing. Return To ...

Difference Between Sag Mill And Ball Mill Solution For Ore

difference between ore dressing and wet ball mill in india. Difference between a sag and a ball mill india the oak tavernifference between a sag and a ball mill difference between a sag and a ball mill is one of the products of our company main products soldit is not only good learn moreag mill vs ball mill samac coal surface mining.

Latest Posts

- موبايل مخروط محطم الزيوليت

- ما هو الاسمنت الدوار

- مطرقة الفحم الهندي الصانع

- الهندي بناء مصنع غسل الرمل

- موردي الركام والحجر المكسور

- جنوب أفريقيا تستخدم الدولوميت محطم

- الأبحاث المتعلقة ب جنوب أفريقيا حجر المحاجر

- الأسطوانة مطحنة الكاكاو

- كيفية جعل الصوت يكفي

- بيع معدن الكالسيت مسحوق طحن

- انفجار الخرسانة سحق عملية ملف قوات الدفاع الشعبي

- المملكة المتحدة الجبس المطحنة للبيع

- جنوب أفريقيا الرمال طاحونة الصانع

- إسفين المتداول مطحنة

- السكك الحديدية المواد الخام مصنع الاسمنت

- Vertical Roller Advantages

- Hyderabad Cement Crusher

- China Vibrating Screen Conveyor Feeding Equipment Supplier

- Production Process Of Concrete

- Barium Sulfate During Copper Anode Casting

- Jaw Crusher Used Model Svedala

- Coal Mine Wage Board Decision

- Jaw Crusher 1974

- Iron Ore Concentration Plant Manufacturer

- Excavtor Hire With A Crusher

- Malaysia Crusher My

- Types Of Cement Crusher And Thier Parts

- Portable Manganese Mobile Crusher In Holy See Sale

- Used Stone Machine For Sale In Gabon

- Conveyor Rubber Type