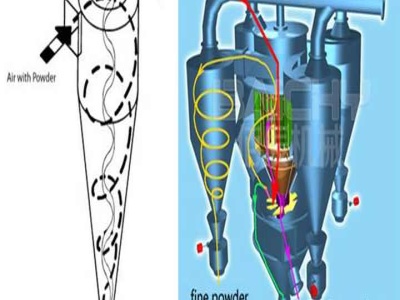

Cone Crusher Discharge Port

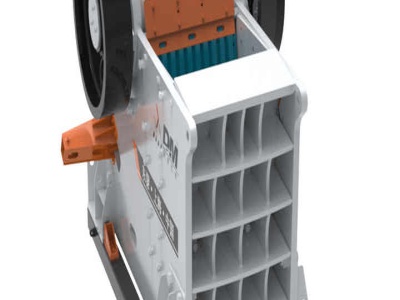

Method for adjusting the discharge particle size of jaw ...

Aug 09, 2021 · The adjustment device of the jaw crusher is an adjustment mechanism for the size of the discharge port of the rock crusher. With the operation of the equipment, the wear of the crushing tooth plate increases, and the discharge port gradually increases, and the size of the crushed product continues to become coarser.

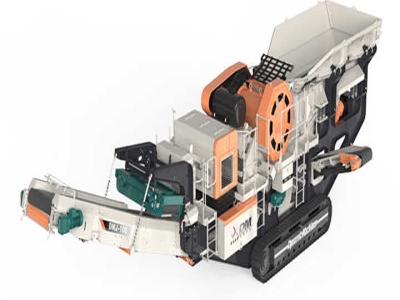

Jaw crusher, impact crusher, cone crusher, mobile crusher ...

The discharge port of cone crusher is adjusted too Unstable voltage. The matters needing attention in using cone crusher. Cone crusher is the common equipments in mining machinery industry . The announcements for daily operations of cone crushers need each worker who operates machinery pay more attention.

Would you like to know 3 ways to improve the efficiency of ...

Aug 21, 2020 · The materials must meet the requirements of the crusher of the cone crusher. Too much or too little material will affect the production efficiency of the equipment. In addition, the operator needs to pay close attention to the discharge situation of the discharge port of the cone crusher, control the speed of the belt conveyor, and ensure the ...

Cone Crusher

The cone crusher is suitable for the medium crushing and fine crushing of ores or rocks whose compressive strength limit is below 300 mpa. It is widely used in the fields of mining, metallurgy, silie and other industries, and generally engaged in the second and third stage of the crushing process in cement to the different crushing principle and product particle size, the ...

How to adjust the Discharge Opening of the Impact Crusher ...

Apr 06, 2021 · 1. The impact crusher with hydraulic driving mode, its main shaft is loed on the plunger in the hydraulic cylinder. By changing the volume of hydraulic oil under the plunger, the upper and lower positions of the crushing cone can be changed, thus changing the size of .

cone crusher,Spring cone crusher factory

When the metal block and other non breakable objects fall into the crusher, the moving cone of the single cylinder is supported by the hydraulic piston at the bottom, which plays the role of adjusting the discharge port, protecting the iron, repeatedly lifting and falling to eliminate the ore blockage.

Crusher plant in South Africa | Gumtree Classifieds in ...

• Spring type cone crusher• 600mm cone diameter• Max feed size: 65mm• Discharge size: 1225mm• 50 ton per hour• 30kw motor needed• Size: 2250 x 1370 x 1675mmStock ID: CONE000Sino Plant is one of South Africa's biggest importers and retailers of building and mining have a range of over 430 products that stretch from tamping rammers to 35 ton ADT's and everything in ...

Sale of various types of mining equipment

Why is the product quality of cone crusher The moving cone and fixed cone of cone crusher are The crushing chamber of cone crusher hasn't been designed Materials do not fit the bill of cone The discharge port of cone crusher is adjusted too Unstable voltage. Read More

How multicylinder hydraulic cone crusher to get better ...

A small crusher can also obtain a better particle size. The output and fineness of multicylinder hydraulic cone crushers are determined by power, crushing force and discharge opening. The way to increase the power is to increase the feed rather than reduce the discharge port. The best crushing power is about 80% of the rated power.

The Impact Rock Crusher Machine VS Hydraulic Cone Crusher ...

Oct 16, 2019 · In addition, the CCM series full hydraulic cone crusher discharge port is adjusted by hydraulic motor. In addition, when the improved bumper and accumulator of the cone crusher machine suddenly increase the iron load, the hydraulic oil of the bumper can instantaneously flow back to the accumulator, and the piston rod can be quickly lifted to ...

HCS Series Hydraulic Cylinder Cone Crusher | mining crusher

Aug 12, 2013 · HCS series Hydraulic Cylinder Cone Crusher adopts the structure of combining spindles floating and hydraulic lifting control system together, and takes discharge port adjustment and overload protect functions into one set, so that to ensure performance while simplifying the structure of the crusher. Compared to other types of cone crusher, it ...

Cone Crusher, Secondary Cone Crusher, Tertiary Cone ...

Structurally, PY series spring cone crusher is simpler, and it can also adjust the size of discharge port by regulating the degree of spring tightness. PY series crusher adopts airproof grease lubriion system, which can effectively isolate dust and lubriing oil so as to ensure the crusher can work stably.

How to solve the dust problem of cone crusher_Jiaozuo City ...

Apr 09, 2020 · The crushed stone needs to enter the conveyor through the discharge port. Due to a certain drop between the feed port and the discharge port, a part of the stone will flow into the air. At the same time, the stone powder will also It rises and spreads around. Understand the reasons for .

What is the cone crusher used for?

Answer (1 of 8): The cone crusher is the most common crusher used in secondarytertiary and quaternary stages of comminution in a crushing circuit. A secondary crushing stage usually uses a standard SD cone crusher and the following stages uses .

Stone Crushing Tool—Multicylinder Hydraulic Cone Crusher ...

Aug 26, 2021 · Performance characteristics of multicylinder hydraulic cone crusher. ... The full hydraulic operating system uses hydraulic cylinders to drive the main shaft to float up and down to adjust the discharge port. In the case of equipment passing iron and cleaning the cavity, automatically adjusted hydraulic pressure can improve efficiency ...

Crusher Machine/Mining Crusher Equipment//Rock Crusher ...

The HPY cone crusher can be produced under a constant discharge port, avoiding the singlecylinder hydraulic pressure floating up and down during the production process, causing the change of the discharge opening, and maintaining the discharge opening constant by rotating the fixed cone adjustment method.

Mining Small Stone Crushing Machine Simple And Fast ...

Mining Small Stone Crushing Machine Simple And Fast Operation And Maintenance Cone Crusher Concrete For Limestone, Find Complete Details about Mining Small Stone Crushing Machine Simple And Fast Operation And Maintenance Cone Crusher Concrete For Limestone,Good Product Shape Crusher Concrete,High Efficiency Jaw Crusher Cone Crusher,Mining Small Cone Crusher from Crusher .

Hydraulic Cone Crusher | Shanghai Dingbo Heavy Industry ...

Hydraulic adjustment of discharge port and overload protection greatly improve the operation level of crusher, making maintenance simpler, operation more convenient and downtime shorter; Series of cone crusher twoway iron release hydraulic cylinder can let the iron through the crushing chamber, the machine in the case of iron and instantaneous ...

MD Series MultiCylinder Hydraulic Cone Crusher AMC Crusher

It is a new generation of products in today's mine construction industry to replace the spring cone crusher and update the general hydraulic cone crusher. Power 220630kw Feed size 0420mm ... The hydraulic motor adjusts the discharge port, which is easy to operate.

Cone Crusher

The Difference Between Cone Crusher and Rotary Crusher . The structure of the grinding chamber is different. The movable cone support model is different. Discharge port adjustment model is different; The safety devices are different. If you want to learn more rotary crusher details, or other crushers, you can consult our staff.

Jaw Crusher VS Cone Crusher | Which Is The Better Crusher ...

Cone Crusher: The motor of the cone crusher drives the transmission shaft to drive the eccentric sleeve to rotate, and the movable cone swings back and forth under the force of the eccentric sleeve, the movable cone is periodically close to and far away from the fixed cone, and repeatedly extrudes and impacts the material until the material meeting the requirements falls to discharge from the ...

Differences Between Singlecylinder Hydraulic Cone Crusher ...

Sep 17, 2019 · Multicylinder: The discharge port adjusting device of the multicylinder hydraulic cone crusher adjusts the adjusting cap by a hydraulic pusher or a hydraulic motor, and drives the adjusting ring to rotate in the support sleeve (the fixedcone spiral rotates up and down) to achieve the adjustment function. The advantage of this adjustment is ...

Difference Between Standard and Short Head Cone Crusher ...

The standard cone crusher has a large head angle, coarser discharge and higher output. It is generally placed behind the rough crusher (jaw crusher or gyratory crusher) for medium crushing. The head angle and the size of the discharge port of the shorthead cone crusher are relatively small, and a finer product size can be obtained.

Four Factors Influencing Product Size of Hydraulic Cone ...

Oct 10, 2020 · Here we share four factors affecting the product size of single cylinder hydraulic cone crusher. 1. The influence of stroke on product granularity. The stroke is the distance from the loose side discharge port to the tight side discharge port of the cone crusher. The stroke has an effect on the particle size of the product.

Latest Posts

- الجرانيت طحن مصنع تصنيع الكلي

- المنغنيز محطم المحدودة

- تغذية الفحم شيرر

- الدولية حجر سحق آلة الصانع

- بيع مصنع الاسمنت القديمة الاندونيسية كيه

- الكوارتز سحق تجهيز مصنع

- ألمانيا تصدير مصنع الجرافيت

- MTM طحن من الصين

- المطرقة محطم الفحم الصغيرة

- أين يمكنني شراء كسارة الرئيسية في الهند

- الهند البنتونيت آلة طحن

- التوازن الشامل مطحنة الأسمنت

- المنشط مسحوق الحجر

- التجارية الثقيلة طاحونة

- RM60 محطم للبيع

- Cone Crusher Manganese Barbecue Stone Crusher Machine

- Cement Mill Hydraulic Roller Up Down With Grinding Pressure

- Wet Screen Mineralwet Screen Ore Beneficiation

- Import Grinding Machine From Marshall Islands

- Bevel Gear Untuk Crusher

- Ce Double Roller Crusher

- Grinding Machine Lubri Ion

- Low Capacity Mobile Crusher

- Malaysian Quarrying Companies Sites

- Ball Mill Trunnion Lining Manufacturer

- Zenith Crushers Oman

- Project Profile Of Crusher Plant

- Feldspar Ball Mill Manufacturer In Germany

- Concrete Crusher Screener Hire Enfield

- Raymond Mills Address