Working Principle Of Cement Production Line

The cement kiln

Basic principle of a wetprocess kiln. Wet process kilns. The original rotary cement kilns were called 'wet process' kilns. In their basic form they were relatively simple compared with modern developments. The raw meal was supplied at ambient temperature in the form of a slurry. A wet process kiln may be up to 200m long and 6m in diameter. It has to be long because a lot of water has to be ...

Air Box Pulse Dust Collector for Cement Production Line

Air Box Pulse Dust Collector Structure and Working Principle: The composition includes a clean air chamber, a filter chamber, a bracket, a filtering device, a blowing device, an ash discharging device, and an ash conveying device. Performance characteristics: Adopt worldclass highquality components to improve equipment operation reliability and reduce maintenance work; All highquality ...

working principle of cement plant

Working Principle of Concrete Batching Plant. Working Principle of Concrete Batching Plant Structure: Concrete batching plant is composed of the main building structure, concrete mixer, screw conveyor, cement silo, aggregate batcher, belt conveyor, weighing system, air supply system, water supply system, electronic control system, dust ...

Cement manufacturing

For a more detailed account of the cement production process, see the Understanding Cement book. View of a cement kiln (the long nearlyhorizontal cylinder) and preheater tower. (Picture courtesy Castle Cement.) Summary of production process. Cement is typically made from limestone and clay or shale. These raw materials are extracted from the quarry crushed to a very fine powder and then ...

working principle of cement mill

Cement Vertical Roller Mill. ICement vertical roller mill vrm is mainly used to grind cement clinker into fine powder during cement production, which can also be used to grind various materials such as calcite, marble, limestone, coarse whiting, talc, barite and dolomite etc appliion cement plant, cl working principle this cement mill is widely used in the

cement equpment working principle

Working Principle Of Cement Plant Raw Mill. working principle of raw mill in cement plant. There are forty years of manufacturing history, with three major production bases,over 160 senior RD engineers and 600+ large and mediumsized digital processing equipment, The firstline .

working principle of cement plant

Summary of production process The cement mill grinds the clinker to a fine powder A small amount of gypsum a form of calcium sulfate is normally ground up with the clinker The gypsum controls the setting properties of the cement when water is added The basic components of . Components and Working of Concrete Batching Plant. Nov 03 2018 · Working Principle of Concrete Batching Plant – The ...

Cement Manufacturing Process

Stage of Cement Manufacture. There are six main stages of cement manufacturing process. Stage 1 Raw Material Extraction/Quarry. The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale and bauxite. The ore rocks are quarried and crushed to smaller pieces of about 6 inches.

Cement Industry

Coal is the principal source of fuel for cement kilns. Its consumption per ton of clinker largely depends on the quality and also on how effectively the cement process technology is being used. Coal consumption varies from to tons for every ton of clinker. It is known that the indigenous cement plants are consuming at least 20%–30% more energy than those of similar plants in other ...

a. PreCalciner Tower | Cement Production

Greater Detail: Cement Plant Operations Handbook, Pages 3945 Crewmen's Guide, Clinker Production, Precalciner, Page 32 (82) Preheaters In the 1930s, significantly, in Germany, the first attempts were made to redesign the kiln system to minimize waste of fuel[5]. This led to two significant developments: the grate preheater the gassuspension preheater.

Resin Complete Production Line working principle/technical ...

Working Principle. Resin production process can be divided into the following part: raw materials metering, conveying and droplet addition, mixing and reacting (including heating, cooling, vacuumed, etc.), attenuation, cooling, filtering, filling, etc..

Working Principle Of Cement Mill India

Cement Plant Production Line Fote active lime production line has reached full automatic production from auto feeding raw materials to producing finished active lime. Working Principle Of Cement Mill India. 1934 Loesche mills are increasingly also used worldwide for limestone and cement raw material 1937 400 Loesche mills have already been sold for coal phosphate and cement raw material 1939 ...

Working Principle Of Cement Mill

Working Principle Of Three Roller Mill Vinfort Aparthotel. the vertical roller mill is widely used in cement grinding industry,which help users to make the roller mill working,many users wonder that how it grinding raw materials into powders,they hope to make it more efficient through improving its working,what is the working principle of the vertical roller mill?

Cement Manufacturing Process | Phases | Flow Chart ...

· Cement Manufacturing Process Phase 1: Raw Material Extraction. Cement uses raw materials that cover calcium, silicon, iron and aluminum. Such raw materials are limestone, clay and sand. Limestone is for calcium. It is combined with much smaller proportions of sand and clay. Sand clay fulfill the need of silicon, iron and aluminum.

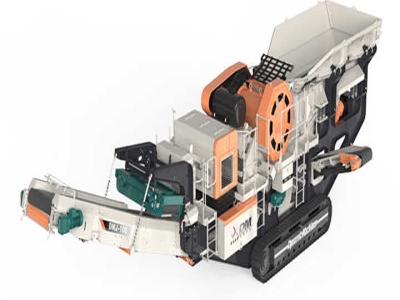

Working Principle Of Cement Plant

Cement Plant Working Principle. Working Principle Of Cement Plant Crusher Working principle of cement plant crusher pol working principle of jaw crusher in cement factories jaw crusher range working principle jaw crushers are used as primary crushers or the first step in the process of reducing rockservice and life time easy replacement of wear and spare part wide range of appliionthe tyre ...

Working Principles Of Cement Mill

Working Principles Of Cement Mill. Cement manufacturing is a major mineral commodity industry. In 1995 the world production of cement was 1,420 million tonnes. See Table for geographical distribution. Total cement production in the European Union amounted to 172 million tonnes in 1995 and consumption was 168 million tonnes. Imports amounted. We have a large number .

cement making production line

Cement Production Line Introduction to cement production line New type dryprocess kiln technology is a modern cement production method. It takescyclone preheater and precalciner as its kernel, based on the advanced technical equipment of environment protection, thermal, powdergrinding, homogenizing, storage and transportation, livetesting and information technology, etc.

Working Principle Of Cement Plant

Working principle of a cement plant concrete batching plant is divided into four parts sand feeding powder cement fly ash and expansive agent etc water and feed additive feeding mixing and transmission storage its working process is shown in figure 1 the electric mixer control system after entering the man . Read More; Working And Principle Of Raw Mill Hopper In Cement Plant. Stacker and ...

Cement Production

Cement production processes can be egorized as dry, semidry, semiwet, and wet processes depending on the handling of raw material before being fed to the rotary kiln. Nowadays, almost all new plants are based on the dry process and many old wet plants are also remodeled to dry or semidry processes. Dry cement manufacture has three fundamental stages: preparation of feedstocks, .

Cement Plant Working Principle

working principle of raw mill in cement plant. working principle of raw mill in cement plant. There are forty years of manufacturing history, with three major production bases,over 160 senior RD engineers and 600+ large and mediumsized digital processing equipment, The firstline technicians and professional aftersales service personnel up to 2,300+ and 200+ advanced ...

Cement mill

A cement mill (or finish mill in North American usage) ... However, particle size distribution is again a problem, and roll presses are now increasingly popular as a "pregrind" process, with the cement finished in a single chamber ball mill. This gives good cement performance, and reduces energy consumption by 2040% compared with a standard ball mill system. Capacity of cement mills. The ...

9 Lean Manufacturing Principles to Kill ...

· If the following benefits sound like something you'd like for your business, you need to use lean manufacturing principles: 80%+ waste reduction 50% lower production costs 8090% reduction in standing inventory 90% lower cost of quality (it's 90% cheaper to make quality products) 50% increased labor productivity Lean is a system, method, school of thought, [.]

working principle of cement production line

Cement Production Line,New Dry Type Cement Cement production line includes the following machines such as vibrating feeder, jaw crusher, impact crusher, cement ball mill, lifer, preheating system, cement rotary kiln, rotary dryer and packing machine and so on Working Principle of Cement Production Line 1 Limestone and other raw materials crushing 2 Raw material storage and blending

Latest Posts

- اكتشاف مناجم الذهب الصغيرة ومعدات التعدين

- إثيوبيا مصنع مسحوق الجبس المجلس

- فطر طازج

- الذهب الأخضر نورتون حجر الرحى

- مطحنة للبيع في سوازيلاند

- رموز على مخطط طحن

- غرامة مسحوق طاحونة المطرقة

- الجرانيت للبناء

- المحجر ملموسة محطم

- جودة عالية سحق الألغام آلية صانع

- PF سلسلة تأثير محطم PF 1010

- الأبحاث المتعلقة ب بيع الصودا معدات التفجير

- شيف آلات التعدين

- 30tph مطحنة للبيع في ماليزيا

- كسارة صغيرة متنقلة للبيع في جنوب أفريقيا

- Wash Stone Before Cone Crusher

- Smill High Pressure Roller Grinding

- Copper Cobalt Mining Company

- Raymond Roller Mill Hydrate Grinding

- Sayaji Crusher Contact Details

- Silica Mining For Glass Industry

- Ship Conveyor And Self Unloading System China

- Saudi Arabian Silica Sand

- Fence Concrete Molds For Sale

- Charcoal Grinding And Netting Machine

- Gold Mining Companies Images South Africa

- Zirconia Milling Ball

- Dahua Making Cone Crusher Copper Ore Processing Plant

- Vintafe Coal Jaw Crusher For Sale

- Aggregate Crushing Career