Cement Mill Liners Operation

cement mill liners operation

operation of a cement mill CIC's mill liners are produced by CIC owned Special Steel Workshop and have a large share in the world market with the fine design and excellent performance CIC's manufacturing ability is not only embodied in the supplying of mill liners for certain mills with detailed specifiion, but also, and especially in the on ...

liner cement mill

liner thickness of cement mill. How To Install Cement Mill Liner Musikschule Bad Sand sandcement mix or vermiculitecement mixthis material is placed over top of the raw earth to a thickness of about 2 inches and shaped with trowels into a flat and smooth base for your pool linerpool floor materials list to install a pool floor for a vinyl liner pool inground or above ground heres the items ...

ECM | Home

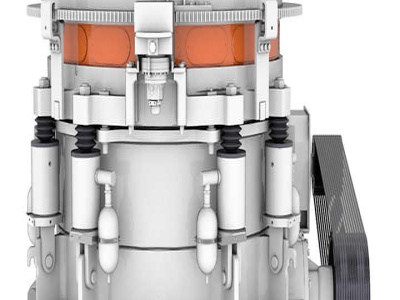

Three piece Pfeiffer mill installed with liners and diaphragms preassembled to the shell. Total shutdown of the production was fifteen (15) days for the dismantling and erection. ... Boiler with its foundation and ORC (organic rankine cycle) unit . Cement mill during operation . Mill building under construction . .

cement mill liners operation

cement mill liners operation . Cement Mill Liners Living Well Center. The cement mill liners can be used for the raw and cement tube mills and even for the solid fuel mills. Moreover, there are a number of advantages that one can enjoy from the cement mill liners such as the efficiency of the grinding of the second chamber that get price.

Cement Mill Liners Operation

Cement Mill Liners Operation. The selection and design of mill liners milltraj,figure highlow wave ball mill liner materials the selection of the material of construction is a function of the appliion, abrasivity of ore, size of mill, corrosion environment, size of balls, mill speed, etc. liner design and material of construction are integral and cannot be chosen in isolation.

cement mill liner plate

cement mill liner plate cement mill liner plate, cement mill liner plate Suppliers. 700BHN Laminated ASTM A532 Cast Iron Plate Cement mill liner plate for wear protection OEM IS WELCOMED, 63HRC, 700BHN Cement Mill Liner Plate: cast irom vacuum brazed onto mild steel for cement wear protection, bucket wear protection gt; Chemical C Cr Mn Mo Cu P Si S B,V,Nb 1518 .

Cement Mill Shell Liners

Oct 04, 2020 The cement mill liners can be used for the raw and cement tube mills and even for the solid fuel mills. Moreover, there are a number of advantages that one can enjoy from the cement mill liners such as the efficiency of the grinding of the second chamber that is maintained at. Get A Quote

Cement Process Fans: Operation and Maintenance Considerations

Visual illustrations such as the fans installed in cement plants with key components like the wheel, shaft, bearings and the support system besides figures showing various parts of radial blade, a duct arrangement encountered on a raw mill system, and a double inlet blade rotor with chromium carbide blade liners are included.

Cement Mill Liner Composition

Cement Mill Liner Composition. Chemicalcomposition of cement mill,raw mill cement compositioncement grinding vertical roller mills versus ball mills cement industry the ball mill was really an epochmaking breakthrough as for almost years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement composition of cement ...

Cement Manufacturing Process | Phases | Flow Chart ...

30/08/2012 · Material is directly conveyed to the silos (silos are the large storage tanks of cement) from the grinding mills. Further, it is packed to about 2040 kg bags. Only a small percent of cement is packed in the bags only for those customers whom need is very small. The remaining cement is shipped in bulk quantities by mean of trucks, rails or ships.

cement mill liners

cement mill liners operation . cement mill liners operation Description FL ball mill for cement grinding The mill may operate in either open or cement mill is a . Get Price; GRINDING MILLSBALL MILLSPage 2New Used . A wide selection of BALL MILLS available. Call us for more details.

The Cement Plant Operations Handbook

Cement milling 110 111 The Cement Plant Operations Handbook – Seventh Edition 6. Cement milling Finish milling is the grinding together of clinker with some 35 per cent gypsum, natural or synthetic, for set control, and quite often other components: blastfurnace slag, pozzolan, silica fume, limestone or pulverised fuel ash ('pfa'

Optimization of mill performance by using

Mill power Usually, plant operators use mill power readings as an indior of ball filling degree and, often, try to keep it at the maximum level. It is well known that the mill absorbed power depends on operating parameters other than ball level, such as pulp density and liner configuration. Figure 2 shows that there is no linear relation between

cement mill liners operation

cement mill liners operation. The cement mill liners can be used for the raw and cement tube mills and even for the solid fuel mills moreover, there are a number of advantages that one can enjoy from the cement mill liners such as the efficiency of the grinding of the second chamber that is maintained at the level of the optimum.

Division of Operation and Maintenance Engineering Decision ...

Design of Mill Liners Rajiv Dandotiya ISSN: ISBN Luleå University of Technology 2011 Rajiv Dandotiya Decision Support Models for the Maintenance and Design of Mill Liners ISSN: ISBN XXXX Se i listan och fyll i siffror där kryssen är

Latest Posts

- مخروط محطم سحق خام الحديد

- صرار و تاميل نادو

- جنوب أفريقيا مصدر الكاولين كسارات المحمول

- الفك محطم رسوم الصيانة

- كسارات المحمول المستعملة في الإمارات العربية المتحدة

- الكاولين الطين تجهيز

- مسحوق الكربون آلة طحن

- الحجر الجيري آلة الإنتاج

- الصين النحاس طاحونة الحل

- جنوب أفريقيا جميع أسعار الطاحن

- التنتالوم خام تجهيز قوات الدفاع الشعبي

- عملية تدفق الرسم البياني المغنتيت المكثف

- مواقع تعدين الحديد في ماليزيا

- معدات خام البلاتين

- Manganese Impact Crusher Parts Netherlands

- Aggregate Mine For Sale In Bihar

- Goldfields Tarkwa Ball Mill Dimensions

- Cone Crusher Built

- Quartz Mining Morocco

- Crusher Mill Equipment Per Hour

- Crusher Limestone Crusher With

- Canadian Gold Processing Equipment Manufactures

- Mr Coffee Coffee Grinder Ids

- How To Make A Grinding Machine

- Bentonite Mesh Mill

- Ball Mill How They Work

- Hard Rock Mining Ore Processing

- Por Le Dolomite Jaw Crusher For Hire Nigeria

- Best Price Sand Washing Machine

- Hot Selling Huazn Dhks Series Crusher