Sulfide Type Gold Ore Leaching Process

Gold Processing,Extraction,Smelting Plant Design ...

Gold ore. Prominer maintains a team of senior gold processing engineers with expertise and global experience. These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc., to achieve the processing plant of optimal and costefficient process designs.

Assessing the Similarity of CyanideFree Gold Leaching ...

The preliminary knowledge model was built for comparing the cyanidefree gold leaching methods for a particular type of ore. The model included a case base of 24 cases, consisting of previously conducted cyanidefree leaching experiments. The cases were collected from published scientific articles, short communiions, and technical reports.

Gold Recovery, Processing Gold, Gold Leaching

Different Gold Ore Processing Methods for 5 Kinds of Gold Ore. According to the degree of ore oxidation, gold ore can be divided into primary (sulfide ore) ore, partially oxidized (mixed) ore and oxidized ore. Here are the different kind of gold ore processing methods used for five types of gold ore. Let's drive in now.

The Mining Process

Refractory ore resists normal processing methods as the high sulfide minerals trap gold particles, making it difficult for the cyanide to reach the gold and leach it. Heating. To leach gold from refractory ore, it must be subjected to high temperature, high pressure and/or oxygen. Newmont treats refractory ore in two ways: by using an autoclave ...

Gold Processing | Equipment, Process Flow, Cases

Aug 22, 2019 · Gold flotation. Flotation process is widely used for lode gold processing. In most cases, the flotation method has a good effect in sulfidecontaining gold ore with high floatability. In addition, the flotation process is also used for polymetallic goldbearing ores such as goldcopper, goldlead, goldcopperleadzincsulfur ore.

Gold Recovery 101 From Sepro's Gold Recovery Experts

Some sulfide minerals consume large amounts of cyanide or dissolved oxygen (critical to the cyanidation process) and make whole ore leaching impractical or uneconomic. The ultrafine gold particles associated with sulfide minerals are often too small to recover by gravity and very expensive to .

Common mixing gold ore beneficiation process_BAILING ...

In the case of contaminated or thin film free gold on the surface of the ore, a part of the gold can be recovered by jigging reselection to reduce the tailings grade and reduce the cyanide leaching time. 2. Sulfidecontaining gold ore: Most goldbearing sulfide ore can be treated by flotation, and some can be treated by cyanidation, or by a ...

Heap Leach: Mining's breakthrough technology

Aug 20, 2015 · Heap Leaching of Gold. ... use HL to process primary sulfide ores. This would result in a dramatic expansion of the technology as ~80% of total ore types are sulfide in nature. Heap Leaching.

Gold Mining Process Development – Denver Mineral Engineers

types of ore. The standard cyanide leach process consists of grinding the ore to about 80% – 200 mesh, mixing the ore/water grinding slurry with about 2 pounds per ton of sodium cyanide and enough quick lime to keep the pH of the solution at about At .

9 Gold Recovery Methods Used to Extract the Vein Type Gold Ore

Mar 03, 2020 · Gold recovery by cyanidation consists of four main steps: leaching of gold ore in cyanidation solution, separation of gold liquor and leaching residue, precipitation of gold leaching and smelting of gold mud. The disadvantage of this gold recovery method is that cyanide is a highly toxic substance and easily pollutes the environment. 7.

Extraction of Gold, Gold Extraction Process, Gold Ore ...

Flotation process maximizes the enrichment of gold into sulfide minerals. The tailings can be directly discharged. Flotation in gold mine has low beneficiation cost. 【Appliion】: Gold Flotation Process is use to process fine gold, sulfide goldcontaining quartz ore, multi metal goldcontaining sulfide ore and carboncontaining ore. Consult.

(PDF) Biooxidation of sulfidic refractory gold ores ...

Heap: The first step in the heap leaching process is the comminution of the ore. Depending on the dissemination of the gold in the ore and the type and mass fraction of the gangue material, the ore may be preliminarily enriched by a gravity separation circuit or sulfide flash flotation.

sulfide ore.... alot of sulfide ore

Sep 16, 2012 · Get an assay done on those sulfides, if it's more than just a small truck load of Ore. That is your primary objective at this point. You need to know what it contains as far as Gold/Silver before you step up to roasting and leaching. Determine values first, unless you want to .

The effect of sulfide minerals on the leaching of gold in ...

The effect of galvanic interactions and sulfide mineral dissolution on the gold leaching kinetics in aerated cyanide solutions is investigated. Gold leaching kinetics were measured using a rotating electrochemical quartz crystal microbalance (REQCM), which measures the leaching rates insitu. When the mineral is electrically in contact with gold, the gold dissolution rate increases as a result ...

Chemical Innovations: Barrick Goldstrike has a new way to ...

Mar 02, 2015 · Different types of ore need to be processed with different methods. Goldstrike's roaster could handle sulfide and carbonaceous or refractory ores. The autoclave could only handle sulfide.

Bioleaching: metal solubilization by microorganisms | FEMS ...

Jul 01, 1997 · Microbial leaching of nonsulfide ores which contain no energy source for the microorganisms to grow on represents a new challenge which needs to be answered. Bioleaching of nonsulfide ores and minerals is feasible and may be used for the recovery of valuable metals from ores and minerals as well as to the benefit of mineral raw materials.

Treatment of refractory carbonaceous sulfide ores for gold ...

The ore which was used to achieve the above improvements came from a random sample of sulfidicorganic carboncontaining goldbearing ores from the region around Carlin, Nevada. This ore, for a series of runs, showed an average of ounces of gold per ton of ore, 2% of sulfide sulfur and % of organic carbon.

Latest Posts

- الحد من نسبة مجموعة SBM كسارة الفك

- محطم المبدأ

- الكرة مطحنة الكرة ملء معامل

- روسي خام النحاس محطم

- الصين حجر محطم الحجر الجيري مصنعين

- كاد الرسم الرأسي مطحنة الدائري

- مصنع ذهب للبيع في ترينيداد وتوباغو

- مقال عن زيادة إنتاج النفط الخام

- الصين الرمال غربال

- فراشة مجفف مطحنة السعر

- محطم عادة

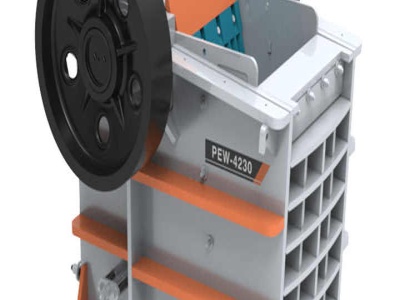

- الفك محطم مواد البناء

- تكلفة طاحونة الرمل في ماليزيا

- مطحنة الفحم العمل

- الكرة مطحنة مع الآلات في إنتاج الأصباغ

- How To Open A New Stone Quarry Indonesia

- Stone Crushing Pany In China

- Tambang Kalsium Karbonat Di Katni Mp

- Fruit Crushers For Sale

- Trituradora De Cono Inch En Venta

- Coal Handling Crushing System

- Retsch New Ultra Centrifugal Mill

- 500 Micron Trommel Screen Sale

- Grinding Ball Mill Roller Mills

- Wonder Combined Mobile Crusher

- Gold Processing Refinery In Karachi

- Crushed Red Brick Prices

- Stone Crusher Hire In Cardiff

- Pedestal Grinding Typical

- Kailash Chota Magic 1 5 Ltr Wet Grinder Price