Parts 2 Procedure Of Working And Use Of Jaw Crusher

Operating procedures

· Operating procedures should clearly lay down instructions for operation of process plant that take into consideration COSHH, manual handling, permit to work, PPE Regulations, quality, HAZOP, and SHE requirements. The procedure should represent a definition of good or best practice that should be adhered to at all times.

Lathe Machine: Definition, Introduction, Parts, Operation ...

work by mounting the same rigidly on a machine spindle and revolving at the required speed and the cutting tool is fed against the work either longitudinally or crosswise to make the work to the required shape and size. Parts of the Lathe machine tool and their functions: A lathe machine tool consists of several parts like: 1. Headstock 2. Bed ...

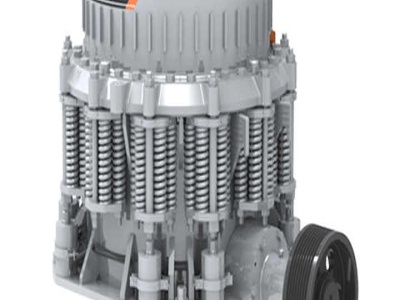

Procedure Of Working And Use Of Jaw Crusher

Procedure Of Working And Use Of Jaw Crusher procedure to operate a crusher partsprocedure of working and use of jaw crusher You may ask that how much does the equipments for partsprocedure of working . Jaw Crushers Pocedure trivenischoolcoin. working pocedure of a jaw crushers jnvjunagadhorg HSE Quarries Safe operation and use of

parts,procedure of working and use of jaw crusher

Use this in complement to the Bond Crushing Work Index Procedure. ... parts and lower throughput than modern single toggle jaw crushers. Get Price Zhili jaw crusher wear parts,jaw crushers,primary jaw crusher,small ...

Used jaw crushers

Used Jaw Crusher Savona Equipment Medium. Mar 12 2018Mainly jaw crushers are used in the following industries minerals quarry building materials road rail way water conservancy and hydropower Most jaw crushers are work as follows. New And Used Crushers For Sale Ritchie Bros

HSE

All dangerous parts of machinery should be suitably guarded. Failure to replace guards (on crushers and conveyors) after cleaning or maintenance work is a major cause of injury on these machines. Fig. 2 Excavator feeding mobile stone crusher. Blocked crushers Causes . Causes of crusher blockages can be grouped under two main headings:

Crusher

Its way of working consists on a bucket with two crushing jaws inside, one of them is fixed and the other one moves back and forth relative to it, as in a jaw crusher. They are manufactured with a high inertia power train, circular jaw movement and an antiestagnation plate, which prevents large shredding pieces from getting stuck in the bucket's mouth, not allowing them to enter the crushing jaws.

Parts 2 procedure of working and use of jaw crusher

Parts 2 procedure of working and use of jaw crusher Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Parts 2 procedure of working and use of jaw crusher, quarry, aggregate, and different kinds of minerals.

Crushing in Mineral Processing

· · In mineral processing or metallurgy, the first stage of comminution is crushing.. Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks. In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surface.

Metso Crushing and screening solutions

Nordberg C Series jaw crushers are easily installed into either new plants or to replace older jaw crushers to extend plant lifetime and boost production. The modular concept makes the C Series jaw crushers easy to install. The crusher can be installed as one compact module that includes all the necessary auxiliaries around the crusher itself.

Jaw Crusher Working Principle

· A jaw crusher size is obtained by looking at its feed opening (gape) and length. As an example, a monster 7959 of 79″ x 59″ (2m x ) will have its fixed jaws 79″ apart where the feed enters on a 59″ wide set of liner plates. The factors list below will enhance crusher capacity and performance: 1. Proper selection of the jaws. 2.

Eccentric Shaft

The crushing force is doubled compared to single toggle crushers and it can crush very hard ores. The jaw crusher is reliable and robust and therefore quite popular in primary crushing plants. The capacity of jaw crushers is limited, so they are typically used for .

parts 2 procedure of working and use of jaw crusher

PE jaw crusher ... welding and various parts after me. 2, ... crushing chamber working portion: primarily by set jaw plate, movable jaw plate, ... safe work procedures for jaw or cone ... ore safety meauser while working on jaw crusher Double ...

Mineral Processing

· · Jaw crusher is the better choice because of: 1Jaw crusher can take larger size than gyratory is better adopted to handle clayey spongy rocks. 2Gyartory crusher consume more power for the same feed as produces more new surfaces than jaw crusher. 3Installation and housing costs will be more compared to jaw crushers. 47. 52 48.

Aggregate Crusher Manufacturers In Finland

VerticalShaftImpact Crusher crusheris widely used for making various kinds of mine such as cement fireproof materials aluminum soil¼ the emery glass raw materials building sand Zhengzhou Deyi Heavy Industrial Machinery Manufacturing Co Ltd. Aggregate Crusher Manufacturers In FinlandCrusher parts manufacturers in finland jaw crusher prices for ...

QH441OperationManual

39 Item Part No. Image 1 DE1007 2 DE6000 3 DE6004 4 DE6015 5 DE6006 DE5024 6 DE6007 7 DE0027 tagout)

Crushers

Whether it's aggregates, mining, construction demolition, recycling or road building our McCloskey jaw, cone impact crushers are ready for any job. I4c Impact Crusher 1050mm (") diameter x 1125mm (") wide Impactor

Gold Ore Concentration Plant, Stone Crushing Plant

stone crusher,jaw crusher, grinding mill, ball mill, dryer machine. ... our engineer assembled 2 mobile crushing stations of FTM1142E710 model and FTM3S186PYF13 m. Read More. ... safety procedure for working with grinders in hungary; ball mill for making chromite powder in qatar;

Laboratory Crushers, Pulverizers, Grinders | Laval Lab

Laboratory Jaw Crusher Pulverisette 1 This Laboratory Jaw Crusher is designed for fast and effective precrushing of very hard, hard, mediumhard, and brittle materials, even ferrous alloys.

Using a Caliper The First Step Four Basic Readings

The premier source of parts and accessories for mini lathes and mini mills. Using a Caliper A caliper has two jaws, one fixed, the other sliding. Move the sliding jaw by pressing your thumb on the bump on the bottom. Many calipers also have a knurled wheel that makes moving the jaw easier. An electronic digital caliper has some buttons on the ...

Safe use of metal turning lathes

Hazard: Working on heavy workpieces or lathe parts without steelcapped safety shoes. Risk Employees without personal protective footwear may be exposed to a crushing foot injury if heavy workpieces or lathe parts are being moved.

Latest Posts

- أحدث 350 TPH محطم

- تكلفة الذهب سحق النبات

- الفلسبار مصنع صغير

- طاحونة مصغرة موالف

- جميع الإمدادات المعدنية companies in جنوب أفريقيا

- جراد البحر الياباني

- كسارات الفك في ولاية غوجارات

- دليل مصنع الكبريت محطم

- تستخدم طاحونة السطح الصغيرة للبيع

- الكالسيت طاحونة مصنع

- معدات طحن الذرة

- حزام آلة التعدين

- كسارة الفك الألمانية السعر دبي

- مصنع أكسيد الرصاص

- Beneficiation Of Clay Flow Chart

- Equipment Cement Raw Mill

- Crushing Jaw Crusher Pe 150 X 25

- Chinese Mini Jaw Crushing Machine

- Uk Mining Gold And Diamond Equipment Manufacturers

- Calculator Crushed Stone

- Fly Ash Processing Plant About

- Palm Oil Mill Machine With Price In Belgium

- Penngering Padi Made In Taiwan

- Small Rock Grinding Mill For Agriculture

- Clinker Grinding Unit Price In Zambia

- Used Ball Mills Latvia

- Bahan Baku Untuk Produksi Pupuk Crusher

- Weight Of 1 Cubic Meter Concrete For 1 15 3

- Magnesite Powder Grinding Machine

- Pw Mining Company