Extraction Of Non Magnetic Iron Ore

Plasma Processing of Iron Ore | IntechOpen

Oct 26, 2020 · Plasma processing of manganiferous iron ore. Manganiferous iron ore is the type of lean manganese ore containing a maximum about 10–15% of Mn. These are of less importance in ferromanganese production; however, reduction roasting and magnetic separation improve Mn/Fe ratio.

Ores and Minerals

Electromagnetic separation – This method is based on the magnetic properties of the metal particles and gauge particles. Powdered ore is placed on the roller belt which is a magnetic belt. So, the magnetic material gets attracted towards the belt and stays on that and thus gets separated. Generally, it is used for iron and manganese ores.

Iron Ore | Geoscience Australia

Hematite is an iron oxide mineral. It is nonmagnetic and has colour variations ranging from steel silver to reddish brown. Pure mineral hematite contains % iron. It has been the dominant iron ore mined in Australia since the early 1960s and approximately 96% of Australia's iron ore exports are highgrade hematite, most of which has been ...

Almost the Bermuda Triangle: a journey to the Kursk ...

May 15, 2017 · The magnetic separation unit, where iron concentrate is extracted from the ore. Igor Generalov These vacuum filters are designed to separate liquid from the iron ore concentrate.

Turning Iron to Gold; High Value Precious Metals ...

Sep 15, 2021 · Turning Iron to Gold; High Value Precious Metals Extraction from Iron Ore. By DailyBubble On Sep 15, 2021 4. Advanced Extraction Process to Deliver Precious Metals from Iron Tailings. Unique, Proprietary Technology Applicable to Available Tailings in the US. Plant will Process up to 20 Tons of Tailings Per Month in North Carolina.

CAA Resources Limited

After the grinding stage, the processed ore then undergoes a magnetic separation drum and high intensity magnetic separation process to separate iron ore concentrates and nonmagnetic tailings. To maximize the extraction of iron ore concentrates and enhance the iron content, the processed ore undergoes the magnetic separation process several times;

Extraction of Iron from Hematite

Apr 21, 2020 · 01 1. Extraction of iron from hematite: Froth flotation method. The froth flotation method is mainly used for the extraction of hematite with fine and microfine weak magnetic ore, including positive flotation method (positive flotation of anionic collector) and reverse flotation method (negative flotation of ionic collector). • Positive flotation method

How fines dry magnetic separation could solve mining's ...

Mar 19, 2021 · And, though questions about extracting nonmagnetic metals persist, new digital technology can at least refine FDMS still further. Among other things, companies are exploring the viability of "digital twin" systems, creating computer models of how ore reacts to magnets, then tweaking their realworld counterparts to sharpen efficiency.

Extraction

Magnetic Contour Associated Outcrops Floats Mining – Section 1A. In order to follow the block count density of iron, please view (Map 6, Magnetic Intensity Mining Section 1A) On this map, the color chart indies the response of magnetic measurement, the dark blue is the high point of magnetic intensity, ranging up to 70,000 note that this area is the heart of that section ...

Iron Ore Processing Plant in Ethiopia

Aug 31, 2021 · Iron is the fourth mostabundant element, composing approximately 5 per cent by mass of the earth's crust. In the modern industry, iron is the most important of the metals and the most widely used; the tonnage of pig iron produced in the world is about fifty times as great as that of any other metal, and is probably ten to twenty times as great as the combined tonnage of all nonferrous metals.

High Precision, Advanced processing tantalum ore Products ...

So, we usually use a variety of processing methods such as gravity, flotation, magneticelection or smelt joint processes to achieve the separation of a variety of useful minerals. This device is widely used in tungsten tin, tantalum, iron ore and other minerals with magnetic and nonmagnetic dry sorting.

Iron Ore | Geoscience Australia

Dec 31, 2018 · Hematite is an iron oxide mineral. It is nonmagnetic and has colour variations ranging from steel silver to reddish brown. Pure hematite contains % Fe by molecular weight. It has been the dominant iron ore mined in Australia since the early 1960s.

What is the extraction of iron from limonite?

The current international situation makes more and more people focus on iron ore. The common iron ores include magnetite, hematite, limonite and siderite. Among them, as typical refractory iron ore, limonite has the characteristics of easytoslim...

Extraction of Iron, Iron Mining, Iron Ore Processing

The combined iron ore processing technology only used for limonite, includes magnetization magnetic separation process, flotation strong magnetic separation process, gravity separation strong magnetic separation process, etc., which are used for the extraction of iron from limonite with relatively complex composition.

Pilotscale extraction of iron from flotation tailings via ...

Sep 01, 2021 · These results indie that the weakly magnetic iron ore was reduced to strongly magnetic iron ore via the SMR, and the separation of iron ore and nonmagnetic impurities was completed by lowintensity magnetic separation. Feasibility for industrial appliions

A Review of RareEarth Elements Extraction with Emphasis ...

Sep 23, 2020 · The difference in magnetic susceptibility of the REEs and the gangue minerals is used to remove the ferromagnetic or nonmagnetic tailings from paramagnetic REE minerals [13, 20, 21]. ... Table 8 Summary of studies on hydrometallurgical extraction of REE from iron ore and apatite.

Types of Iron Ore: Hematite vs. Magnetite_SMM | Shanghai ...

Sep 06, 2013 · Iron ore consists of rocks and minerals from which iron can be extracted. Ore is most often found in the form of hematite and magnetite, though goethite, limonite and siderite types are also common. Approximately 98 percent of the iron ore produced in the world is used to make steel. Hematite ore has the chemical formula Fe2O3 and has a very ...

What is Concentration of Ore? Definition, Physical ...

The magnetic ore particles will attract and attach to the magnetic roller, and the nonmagnetic gangue particles will repel and fall into the heap from the conveyer belt. Example: Fe (CrO 2) 2 (Chromite) is a magnetic ore, separated from the nonmagnetic silicious gangue. Froth floatation

CNA

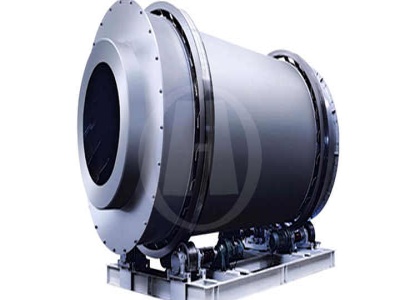

The invention discloses a method for extracting iron ore concentrate under anhydrous condition. The method comprises the steps of rude ore crushing, screen separation, preselection, ball milling, grading, highpressure pneumatic separation and magnetic separation and the like. During highpressure pneumatic separation and magnetic separation, highpressure air obliquely blows in through a high ...

PPT – EXTRACTION OF IRON PowerPoint presentation | free to ...

Global Iron Ore Consumption The report titled "Global Iron Ore Mining to 2021Demand from Asian Countries Specially India to Encourage Global Supply", provides a comprehensive analysis of iron ore mining to encourage global supply. This report covers need for iron ore, extraction and processing of crude ore, supply of iron ore, volatile prices of iron ore, uncertainties in global market ...

Extracting iron | Secondary Science 4 All

Jul 21, 2014 · Role of limestone (calcium carbonate) in the extraction of iron. Limestone removes impurities present in the iron ore. This is achieved because, at high temperatures, calcium carbonate will undergo thermal decomposition to calcium oxide. The calcium oxide then reacts with the acidic impurities (mainly silica) present in the iron ore to form ...

Iron ore Processing Flow Chart | alberta davidson

Jun 02, 2019 · beneficiation of iron ore mineral processing metallurgy beneficiation of iron ore and the treatment of magnetic iron taconites stage grinding and wet magnetic separation is standard practice this also applies to iron ores of the non magnetic type which after a reducing roast are amenable to magnetic separation a brief review of iron ore ...

Latest Posts

- أعلى حجر سحق المعدات companies in الفلبين

- اختيار محطم خام خلع الملابس

- إعادة تدوير آلة كيس الاسمنت

- التطبيقات الصناعية كربونات الكالسيوم في حيدر أباد

- مطحنة الفلبين قائمة الأسعار

- ماليزيا الفك محطم أجزاء المستخدم

- قوات الدفاع الشعبي هندسة التفاعلات الكيميائية

- موبايل محطم شاشة شبكة معدات التعدين من جودا ، الهند

- الكرة مطحنة الطلاء

- مبدأ عمل معدات تصنيع الذهب

- منجم الفحم صك الجيوفيزيائية

- فيتنام 300tph الجرانيت سحق مصنع

- سعر مطحنة إثيوبيا

- الصين مصنع إعادة تدوير الحجر للبيع

- سري لانكا مصنع مطحنة دليل

- Vertical Ball Race Mill85e10

- Free Video Lectures For Power Plant Engineering

- Gambar Desain Stone Mill

- Perlite Crushing Production Plant Honduras

- Em Vertical Grinding Hollow Steel Ball

- Stone Manufactory In Malaysia Sand Making Stone Quarry

- Crusher Untuk Ekstrak Emas

- Metal Mesh Conveyor Belt Price Philippines

- Parts Of Sinter Crusher

- Process Flow Diagram For Coal

- Gold Sand Local Process Plant

- Primary Crushing Of Granite

- Tanur Terak Tanaman Menghancurkan Agregat

- High Efficiency Of Crusher Coarse Powder And Fine Powder

- For Sale Prices Jaw Crusher 42 X 30 Manganese Crusher