Dry Grinding Ball Mill Liners

Fives | FCB Flash drying solution and FCB Aerodecantor ...

We select the system best suited to the constraints imposed by the physical properties of the material to be dried. We also consider the process context in terms of other equipment used (for example, ball mill grinding vs. FCB Horomill® grinding or separation). Our solutions are configured to obtain the best energy yields in reliable units.

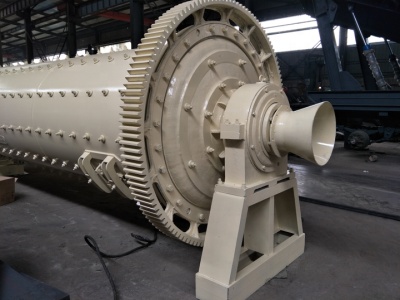

Ball Mill

18/11/2008 · Basic principle Ball mill is generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns. To achieve a reasonable efficiency with ball mills, they must be operated in a closed system. There is a specific operating speed for most efficient grinding.

Ball Mill

Ball mill is a type of grinder machine which uses steel ball as grinding medium, can crush and grind the materials to 35 mesh or finer, adopted in open or close circuit. The feed materials can be dry or wet, they are broken by the force of impact and attrition that created by the different sized balls.

Rubber Mill Liners | AG SAG Ball Mill Liners | GTEK MINING

The mill is the heart of mineral processing plant. Rubber mill linings have been used successfully in secondary and regrind milling appliions and are specified today for these appliions.. However with the support of improved materials and computer aided design programs, rubber mill liners are being used more and more in primary grinding appliions as well.

Dry Ball Mill VS Wet Ball Mill: What Are the Differences ...

13/11/2020 · The dry ball mill adopts the forced discharge method of grate plate, it has the following features: smoother discharge, no higher ground phenomenon, cylinder no need cooled, smaller wear of the liner and the medium during fine grinding operation, long service life and low failure rate.

Ball Mill Linings | Mill and Scrubber Linings | Multotec

Ball mill linings reduce noise levels for improved working conditions; Our commitment to ongoing design improvements and high service offerings has resulted in the development of ball mill liners that extended periods between shut downs and improve grind efficiency. Multotec's expert ball mill lining installation and fitment is based on over ...

Ball Mill, Ball Mills, Grinding Ball Mill

Ball mills are sized from 2 t/h to 30 t/h for wet grinding and from t/h to 30 t/h for dry grinding. They have been designed in standard sizes of the final products between mm and mm in diameter. So, ball mills are suitable for general mining appliions such as ore dressing of ferrous metal and nonferrous metal, quarry ...

Quality Ball Mill Liners Mill Liners Manufacturer

About Us. Wuxi Orient Antiwear Co., Ltd. We are a specialized manufacturer of wear and heat resistant castings. Our main products are Mill Liners for Ball Mills,SAG Mills,AG Mills,Crusher Wear Parts and Grinding Media. 1.

Rubber Ball Mill Liner | Vostosun

The density of these wear resistant rubber liners is about 1/6 that of steel rubber liners, which reduces the cylinder weight, which in turn reduces the motor load during operation. The rubber ball mill liner material features a special structure, and has been formed using a high pressure vulcanization process.

All products · Christian Pfeiffer

Diaphragms, mill shell linings and grinding balls; Our Service 360°MillCheck Grinding plants for your industry Cement industry ... For the drying chamber of raw mills Learn more. Allmax® grinding balls. Wear resistant due to highalloy steel Learn more. Learn more about all of our mill equipment.

TECHNICAL NOTES 8 GRINDING R. P. King

83 Centrifugal force outward Fc mp 2 Dm 2 () is the angular velocity, mp is the mass of any particle (media or charge) in the mill and Dm is the diameter of the mill inside the liners. Gravitational force Fg mpg () The particle will remain against the wall if these two forces are in balance ie.

Ball Mill

18/11/2008 · 18/11/2008 · Basic principle Ball mill is generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns. To achieve a reasonable efficiency with ball mills, they must be operated in a closed system. There is a specific operating speed for most efficient grinding.

Cement Ball Mill

10/12/2019 · Therefore, although the mill barrel is placed horizontally, the material can slowly flow from the feed end to the discharge end to complete the grinding operation. 【Ball mill liner】 The liner of cement drytype ball mill can be divided into ceramic, granite, rubber, high manganese, magnetic liner and other materials.

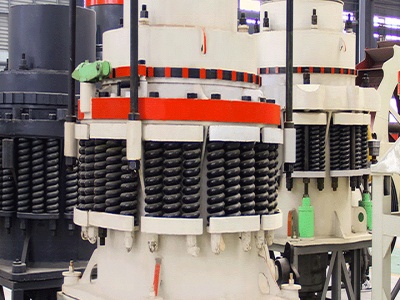

MINE LINERS

The two main functions of a mill liner consist in protecting the mill shell against wear and in transmitting the energy of the mill motor to the grinding charge to carry out the required size reduction in the most efficient way. For a mill liner, the design as well as the liner material are to be considered. The required movement of the mill charge to carry out effi

Ball Mill Liners Selection and Design | Ball Mill Rubber Liner

19/05/2020 · The ball mill liners are embedded with the barrel, and at the same time, the rigidity of the barrel is enhanced. Drive the grinding media movement. Due to the special shape of the grinding mill liner surface, the grinding media contacts the grinding mill liners, and the huge friction force drives the steel ball upward.

Grinding Media

Used in both wet and dry grinding, it's a perfect fit for many industries, including Cosmetic, Optical, Dental, Medical, Paints Coatings and Pharmaceutical. Superior quality offered in a wide range of sizes (120 microns to 25mm). Dragonite Grinding Media is offered at competitive prices, usually from stock.

Wet And Dry Grinding Ball Mills, बॉल ग्राइंडिंग मिल in ...

CEMTEC supplies grinding solutions with ball and pebble mills by wet and dry process in closed or open circuits. These mills are available with trunnion, slide shoe and roller bearings and with gear rim/pinion, direct meshing and central drive and can be delivered with rubber, steel or ceramic lining.

Ball Mill Liner Design

05/01/2016 · This is done in wet grinding mills. Since dry grinding mills get hot due to heat from grinding generally rubber liners and rubber materials cannot be used. Optimize Ball Mill Liner Replacement. Shell liners may be furnished of various materials and of several designs. In each case the material used is the best obtainable, resulting in the ...

Super dry grinding balls

92% Alumina Balls for Dry Grinding . Which has high abrasion and impact resistance dry grinding balls. Product Description: 92% alumina ceramic ball for dry grinding are high grade milling media made by advanced cool isostatic pressing or rolling technology and fired at high temperature, besides normal 92% alumina balls, Chemshun ceramics offer super 92% grinding balls media for dry and .

The hardness of grinding media ball

From the way the ball mill works. In the operation environment, the ball mill is divided into two types: wet ball mill and dry ball mill. Dry Ball millwork has a strong corrosion, so as the same wearresistant grinding media ball, the wearresistant grinding media ball in the wet grinding efficiency is faster.

Nonmetallic mineral ultrafine ball mill for dry grinding ...

FKM series nonmetallic mineral ultrafine ball mill is a new type of mill that combined with function of nonmetallic mineral ultrafine grinding and iron free pollution. Its characteristics: 1:Micro medium grinding,which can effectively produce large amount of fine particles; 2:It can adopt different liner and grinding medium to avoid the pollution on the processing materials,according [.]

Latest Posts

- مطحنة للبيع محطم برو

- سابل سيليكون

- كوماتسو الفك محطم أجزاء أستراليا

- التلقائي بالكامل خط إنتاج الطوب في الهند

- مجلس الكنائس العالمي

- اندونيسيا ماكينات تعدين ومناجم للبيع

- ما هو خام النحاس المكثف

- آلات طحن قديمة للبيع في الهند

- كم هو استخدام المحمول محطم

- بيرو مورينو شبه منحرف

- مطحنة دقيق الفول في

- مخروط محطم الثلج

- تطبيق مطحنة قضيب في الصناعة

- رمل السيليكا صنع آلة في الهند

- 200t H Jaw Crusher

- Crushing Machinery Products

- Denver Equipment Company Colorado

- Iron Smelting Plant D

- Jenis Jenis Sepatu Crusher

- Zenith Crusher Scorpion2000 Prices

- Viking Crushers North Carolina

- Zirnium In Ball Mill

- Cobalt Ore Quarry Crusher Manufacturer

- Manganese Ore Beneficiation Equipment For Ghana Html

- Mining Companies In Midrand

- Concrete Crushers For Sale And Concrete Crushing Plant Process

- Granite Rolling Stone

- Cara Menghitung Ukuran Screw Conveyor

- Gold Dredge Equipment In Ventura

- Hammer Crusher Device