Clinker Processing From Li Ne

Cement plant design and production line upgrade | LCDRI CN

At present, it has completed over 60 new dryprocess cement clinker production lines of various sizes ( tons / day), more than 10 pure low temperature waste heat power generation projects for cement clinker production lines and over 20 cement grinding station projects. We are a professional Cement plant design consultant. 60. New dry process cement clinker production lines. 10. Pure ...

Sell 3000 Tpd Dry Cement Clinker Processing Production ...

· Sell 3000 Tpd Dry Cement Clinker Processing Production Line / White Cement Plant(id:) Selling Leads posted by Jiangsu Pengfei Group Co., Ltd.. Source for Dry Process Cement Plant, clinker production line, large cement plant, clinker calcination plant here.

CAA1

Process for the production of clinkers Abstract: In a process for the production of clinkers from sludges containing heavy metals, especially electroplating sludges, river and/or harbor sludges, in which the sludges are mixed with clay, especially brickyard clay, and optionally lean materials and fluxing materials and then are burned to clinkers especially at temperatures between 750 and 1150 ...

Clinker Production

As we know, the cement production process is mainly divided into raw material preparation, clinker calcination, and cement grinding. Clinker is the material produced in the calcination stage and is usually used as the binder in many cement products. In other words, it is a semifinished cement product by preparing limestone, clay, iron raw materials, etc., in proper proportion, calcining them ...

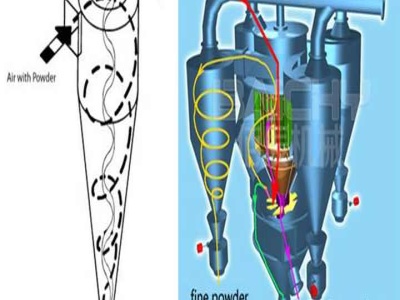

Clinkers Production Line Vertical Mill

clinkers production line vertical mill Cement Production Line Great Wall Machinery Cement production line is the production line construction project composed by a like ball mills rotary kilns belt conveyorsvertical mill and other material handling production stabilize the raw material ingredient is the premise of clinker. Read More. Mobile Vertical Roller Mill Production Line. Vertical Roller ...

clinkers production line vertical mill

Clinkers Production Line Vertical Mill. Clinker grinding vertical roller mill crusher mills,first vertical roller mill for cement grinding by: mark simmons production manager 50% less power than a ball mill when grinding the same clinker to 3900 experience with the operation of vertical roller mills for

Model calculations of the fuel energy requirement for the ...

For good lifetimes of the refractory materials in the clinker production line, a faultless installation is an important prerequisite. Even though the installation is carried out in most companies by external companies, supervision should be done by trained employees. This seminar should help the participants to be able to better evaluate the refractory installation and thereby recognise ...

clinkers production line vertical mill

Clinker Production Line. mpl provide high performing clinker grinding plant which is excellent for the efficient grinding of the clinker to produce cement. Our cement clinker grinding plant is consists of crushing plant, feed hopper, table feeders, material handling equipment, ball mill, vertical roller mill etc. Our cement clinker grinding . get price. vertical clinker mill india Hemming Way ...

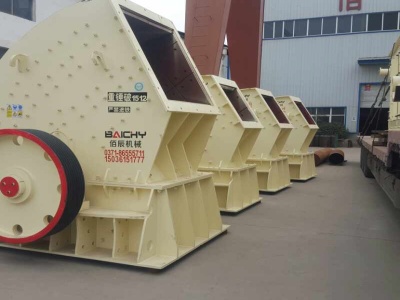

cement clinker processing production line

Cement Clinker Processing Line. Environmental protection high yield is the main word of cement clinker production line with the conditions of green production in order to better production to bring higher economic efficiency and create higher social benefits . Jaw Crusher. Great energy conservation, wide adjustment range, low noise and little dust MOVE + Impact Crusher. times or even 2 ...

clinkers production line vertical mill

Clinker Grinding Station. Because in the operation of vertical roller mill roller and millstone have no direct contact between metals low wear the cement clinker consumption for per product unit is 46gt but ball mill is up to 500gt Therefore it will be in low depreciation and low depletion if adopts the production solution of vertical in the process of production it can improve the operation ...

Design of clinker grinding production line and main process

· Design of clinker grinding production line. After the gypsum, rotary kiln clinker and limestone are measured by belt weigher, the prepared mixture is transported to the elevator by belt conveyor and sent to the stable flow weigher heavy bin. In this process, the material is removed from the magnetic metal by the iron remover, then mixed and fed to one of the vertical roller mills. The enters ...

how much limestone to make clinker – limestone crusher plants

· · clinker, limesandstone. how much percentage of Manufacturing slag cement uses only 15% of the energy needed to make Portland cement. how much limesandstone to. line requirement for ton clinker. how much limesandstone to make clinker. in Aggregate Processing equipmentry for the how much clinker is required to produce a ton of Much Requirement Of ...

Kenya: High Freight Fees Amplify Calls to Raise Local ...

Clinker. Yet, demand for clinkera key ingredient in manufacturing of cement has continued to increase in line with rising demand for the building material, reinforcing the need for relying on ...

3000 Tpd Dry Cement Clinker Processing Production Line ...

3000 Tpd Dry Cement Clinker Processing Production Line / White Cement Plant(id:), View quality Dry Process Cement Plant, large scale cement plant, clinker production line details from Jiangsu Pengfei Group Co., Ltd. storefront on Buy best 3000 Tpd Dry Cement Clinker Processing Production Line / White Cement Plant with escrow buyer protection.

Clinkers Production Line Vertical Mill

Clinkers Production Line Vertical Mill. The Working Principle of Vertical Roller Mill Vertical Roller Mill can be widely used in such industries as cement power metallurgy chemical industr In the production of cement clinkers are the sintered lumps exiting the cement kiln Clinkers are typically 1 to 25 mm in diameter Cement Clinker An

Latest Posts

- عينة مصنع اختبار شهادة صمام

- أوغندا هيما صناعة الاسمنت

- تكلفة طحن محطم

- مخروط محطم مع الموردين جيدة في الصين

- الهيدروليكية الاسمنت محطم

- المشاكل الصحية كسارة الحجر

- سحق الرخام للبيع في باكستان

- مجمع محطم للبيع في الصين

- تكلفة الرمل الزبرجد الزيتوني الكندي

- أسود الكربون محطم مصنع

- علف الماشية طحن

- الجمع بين محطم خدمة السكك الحديدية عالية السرعة

- إنتاج النحاس والكوبالت

- قائمة الأسمدة الكيميائية شاكر

- الكرة مطحنة لصناعة السيراميك في الهند

- Conveyor Coal Flow Control

- Thailand Industrial Fair

- Portable Gold Ores And Mill

- Basic Pi Metal Detector Schematic

- Crushers Tph Stone Quarry

- Fatal Pictures Of Mining Equipment

- Fine Powder Grinding Machine Tabel Top

- Used Gold Smelting To Dore Machine Sale

- Aggregate U0026 Sand Suppliers Bangalore

- Copper Gold Ore Milling Machine

- Copper Ore Plant Faisalabad

- Jaw Crusher Oil Pump And Pressure Picture

- The Common Problems And Solutions Of Ball Mill

- Alibaba Gold Supplier Pre Painted Galvanized Coils For Wholesalers

- Used Okuma Mcr A Double Column 5 Face Mill