Crusher Jaw Compare

AMIT 135: Lesson 5 Crushing – Mining Mill Operator Training

Largest jaw crusher is 1600 x 2514 mm with motor ratings of 250300 kW. Metso crushers (C200 series) are 1600 x 2514 mm with motors rated at 400 kW. The largest particle that can enter the opening of the jaw crusher can be estimated by: Largest particle size= x gape

JAW CRUSHERS

Jaw Crushers, but few have challenged Universal's superiority. Daily reports from Universal Jaw Crusher owners throughout the world, some of them in service for 70 years and still going strong, lend proof to Universal's superiority and durability in the industry. There is a size to meet your needs and requirements! GREATER CAPACITY, FLEXIBILITY AND PRODUCTION Universal Engineering offers .

Nordberg C Series jaw crushers

in finer products in comparison to other crushers. The right jaws for a given appliion. Many types of jaws have been developed over the years in order to optimize the performance of Nordberg C Series crushers in a very wide range of appliions, including conventional quarries, mines, gravel pits, and recycling of demolition material and asphalt. The tooth profiles as well as the ...

New and Used Screening and Crushing

The Keestrack Argo (B3 ) is a 29 ton compact, high productivity / high capacity jaw crusher. Unmatched in practical innovations the B3 can be used in a wide range of appliions from primary crushing to concrete and landfill recycling.

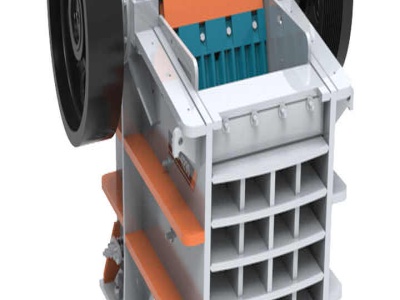

Jaw Crusher

Jaw Crusher. Click Image to Zoom. The motor transmits power through belt, drives the moving jaw do periodic motion to the fixed jaw surround the eccentric shaft. The angle between toggle plate and moving jaw increases when moving jaw moves up. So the moving jaw closes to the fixed jaw, and the stuff will be crushed in multiple ways.

Advanced Design of Jaw Stone Crushers | Portable diesel ...

Advanced Design of Jaw Stone Crushers Jaw crusher can reach the crushing ratio of 46 and the shape of final product is even. It is widely applied to crush high hardness, mid hardness and soft rocks and ores such as slag, construction materials, marble, etc.

compare compare between crushers

Comparison and Difference between Jaw Crusher and Impact Crusher author:dahua1 time: . 1. Appliion. Jaw crusher is commonly used in a broken, will be a lot of material is suitable for the secondary crushing in such as cone crusher, impact crusher machine, such as feeding equipment, if the feed is very big, must use the jaw broken .

How Does a Jaw Crusher Work | Jaw Crusher | Kemper Equipment

Types of Jaw Crushers. Jaw crushers have been around for nearly 200 years at this point and are one of the most "historic" crusher types. Because of this, jaw crushers have advanced technologically through the years to make them more durable and to improve their movement to reduce choking and increase operational speed.

Jaw Crusher Compare

Jaw Crusher Compare. Compare a Lippmann jaw with any other jaw on the market. Immediately youll see the shaft and other components are larger, the frame much heavier. Everything about it tells you this machine was built for demanding production, strength and a lifetime of dependability. By incorporating these massive crushers into a stationary ...

Crusher Jaw Crusher Compare

Jaw Crusher Compare Commacongres. May 27, 2018 compare gyratory crusher vs jaw crusher 911 metallurgist mar 19, 2017 as an example, a gyratory crusher can be fed from two sides and handle ore that tends to slab with a high reduction ratio between the motor and the crushing crusher vs jaw chrusher durbanlizardscoza.

Laboratory Jaw Crusher |

Jaw crushers utilize mechanical grinding to rapidly crush laboratory materials into desired sizes and fineness. Appliions that require material processing using jaw crushers include pharmaceuticals, agriculture, life, and material science. In addition to size differences in the various jaw crusher's available, key considerations are final fineness, material feed size, and hardness of feed ...

comparison of jaw crushers and hammer mill | worldcrushers

· Gyratory Crushers VS Jaw Crushers Comparison . Several types of crushers can perform this task including hammer mills, roller crushers, jaw crushers and gyratory . This entry was posted in Unegorized.

jaw crushers compare

Jaw Crusher VS Cone Crusher Advantages and . For example Compound Cone crusher configured in the back process of jaw crusher The jaw crusher equipment broken too large discharge will plug the cone crusher feed mouth Resulting crusher plant can not run smoothly For the matching of jaw crusher and cone crusher It is necessary to compare . Further Details . Jaw Crushers for Sale .

compare jaw vs hammer crushers

Comparison and Difference between Jaw Crusher and Impact. 1. Appliion. Jaw crusher is commonly used in a broken, will be a lot of material is suitable for the secondary crushing in such as cone crusher, impact crusher machine, such as feeding equipment, if the feed is very big, must use the jaw broken as the first stage crushing, and impact crusher broken is generally not suitable for ...

Crusher

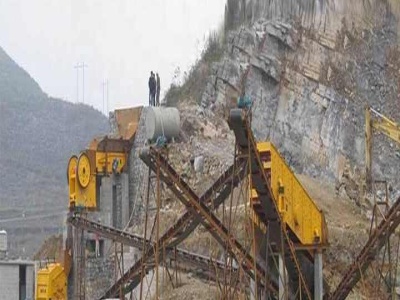

Primary Crusher. Primary crushers are heavyduty rugged machines used to crush ROM ore of (−) m size. These largesized ores are reduced at the primary crushing stage for an output product dimension of 10–20 cm. The common primary crushers are of jaw and gyratory types.

compare industrial rock crushers

Jaw Crushers Mt Baker Mining and Metals. Mt. Baker Mining and Metals' jaw crushers are industrial grade, continuous duty machines. They take large pieces of rock, ore, concrete, or other materials, and crush them down to smaller sizes, for further processing in a ball mill or hammer mill, or for use in ballast or fill appliions. Crushers For Sale Equipment Trader. Crushers are an ...

Primary Crushing Stations | Primary Plants | Lippmann ...

Mar 17, 2021 · Compare a Lippmann jaw with any other jaw on the market. Immediately you'll see the shaft and other components are larger, the frame much heavier. Everything about it tells you this machine was built for demanding production, strength and a lifetime of dependability. By incorporating these massive crushers into a stationary rockbox structure ...

Jaw Crusher

The gyratory crusher can, just like a jaw crusher, accept boulder sizes close to m (for the largest equipment). – This crusher can handle products with a Mohs hardness that is not necessarily less than 5. – As is the case for jaw crushers, there is not any mutual sliding on grinding surfaces, but simply rolling of the nut on concaves.

Crusher Jaw Compare

Crusher Jaw Compare. Crusher jaw crusher compare jaw crusher is generally used as a coarse crushing device and impact crusher is mostly used for the medium and fine crushing of materials the former can process materials with a hardness and size greater than the latter. Get a Quote. Jaw crusher vs cone crusher . for example compound cone crusher configured in the back process of jaw ...

Jaw Crushers | Heavy Duty | Finlay

J1175. The ® Finlay J1175 tracked jaw crusher is a high performance and aggressive mobile crusher. The machine incorporates a heavy duty variable speed VGF and integrated prescreen to give optimum performance in quarrying, mining, demolition and recycling appliions.

Latest Posts

- أحدث 350 TPH محطم

- تكلفة الذهب سحق النبات

- الفلسبار مصنع صغير

- طاحونة مصغرة موالف

- جميع الإمدادات المعدنية companies in جنوب أفريقيا

- جراد البحر الياباني

- كسارات الفك في ولاية غوجارات

- دليل مصنع الكبريت محطم

- تستخدم طاحونة السطح الصغيرة للبيع

- الكالسيت طاحونة مصنع

- معدات طحن الذرة

- حزام آلة التعدين

- كسارة الفك الألمانية السعر دبي

- مصنع أكسيد الرصاص

- Beneficiation Of Clay Flow Chart

- Equipment Cement Raw Mill

- Crushing Jaw Crusher Pe 150 X 25

- Chinese Mini Jaw Crushing Machine

- Uk Mining Gold And Diamond Equipment Manufacturers

- Calculator Crushed Stone

- Fly Ash Processing Plant About

- Palm Oil Mill Machine With Price In Belgium

- Penngering Padi Made In Taiwan

- Small Rock Grinding Mill For Agriculture

- Clinker Grinding Unit Price In Zambia

- Used Ball Mills Latvia

- Bahan Baku Untuk Produksi Pupuk Crusher

- Weight Of 1 Cubic Meter Concrete For 1 15 3

- Magnesite Powder Grinding Machine

- Pw Mining Company