What Is The Main Equipment Of A Cement Grinding Plant

grinding plant difference between concrete and cement

The cement clinker grinding plant or cement grinding station acts as an individual production line while in the final period from the cement production course of action Within the finished product time period the cement clinker is ground by including reasonable mixing products and after that forms the completed cement . What is the Difference Between Concrete and Cement Oct 05 2019 · The ...

CEMENGAL. Engineering, equipment and assembly for the ...

25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding Station, cement plants, cement silos, vertical mills, horizontal mills, PLUGGRIND modular and portable grinding stations. 25 años en la industria del cemento suministrando ingenieria y equipos para montaje y puesta en marcha de moliendas de cemento y .

equipment of grinding cement plant in netherlands

25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding Station cement plants metallic and concrete silos vertical mills horizontal mills PLUGGRIND modular and portable grinding stations ...We are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and other sandstone ...

CCG Plant | Loesche

LOESCHE CCG Plant for Siam City Cement Sri Lanka. Galle LOESCHE is supplying a CCG grinding plant for Siam City Cement Ltd. (Lanka) which will be used in the harbour area of Galle on the southern tip of Sri Lanka as part of an expansion of the Ruhunu cement plant.. A wide variety of cement types can be produced with the compact CCG grinding plant.

grinding process in cement plant

grinding process in cement plant The Cement Manufacturing Process Cement Manufacturing Process. The cement manufacturing process starts with the mining of limestone that is excavated from open cast mines. Then this limestone is crushed to 80 mm size and is loaded in longitudinal

coal grinding mill in cement plant

It is the main equipment of cement plant, used for drying and pulverizing coal mainly consists of the feeding device, main bearing, rotary part, transmission device, discharging device, the highpressure starting device, and lubriion system. Coal Grinding Cement Plant Optimization. Most commonly used mills for coal grinding in cement plants are closed circuit air swept (Single ...

Éric Edet, Product Manager, Fives FCB, France, uses the ...

The main equipment used at the grinding plant ... cement. The main equipment of the grinding plant is listed in Table 1. Commissioning The contract was effective from October 2004. The main equipment was delivered within just 16 months notable when a steady demand for steel and Table 1. Main equipment of the grinding plant Equipment Supplier Size/type Installed power (kW) 2 x HOROMILL ...

Clinkerization

Main factors dictating size of kiln are the retention time (2530 minutes) of material in kiln, degree of filling (1017%) and thermal loading of burning zone ( x 10 6 kcal/h/m 2). Precalciner kilns are shortest in length, as 9095 % calcination is completed outside the kiln. L/D of three tyre kiln is between 1417 and for new kiln like 'Rotax kiln' it is only 1213. Kilns are ...

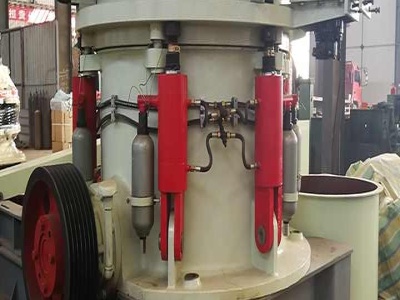

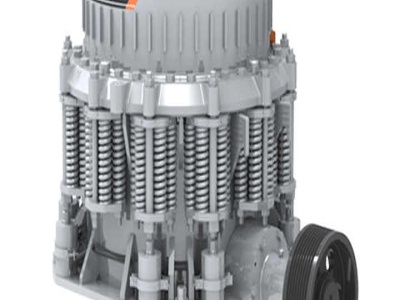

what is the main equipment of a cement grinding plant

Cement production line,Cement making plant,Cement equipment,Cement..... limestone is the main raw material for cement making, ... Related equipment; Features; ...They are used for crushing and grinding coal into powder in cement plant.

Teresa plant, the Philippines: cement grinding plant.

grinding and two for cement grinding, as part of the new 3300 tpd production line. The raw grinding plant is similarly fitted with the FCB Aerodecanter – Flash dryer within the FCB TSV™ classifier gas circuit, as the total feed moisture can reach up to 6%. Performances of the grinding plant were successfully met, with a production in excess of 300 tph of raw meal at R90 µm = %, an ...

Manufacturing of Portland Cement – Process and Materials ...

· The manufacture of Portland cement is a complex process and done in the following steps: grinding the raw materials, mixing them in certain proportions depending upon their purity and composition, and burning them to sintering in a kiln at a temperature of about 1350 to 1500 ⁰C. During this process, these materials partially fuse to form nodular shaped clinker by broking of chemical .

Cement manufacturing

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc.. For information on materials, including reactions in the kiln, see the ' Clinker ' pages. For a more detailed account of the cement production process, see the ...

The essentials of electrical systems in cement plants

· In a cement plant also there is a 'mini grid' receiving power from main electricity grid and also from plant's captive power plant. They have to work simultaneously and hence should be 'synchronized' when working in parallel,, the voltage, frequency and phase must match.

Cement Plant

The next evaluation targeted the economic performances of the cement plant with carbon capture. For estimation of the capital expenditure (CAPEX) as well as the specific investment costs (reported as Euro per ton of cement), the cost correlation method was used (Smith, 2005).The key mass and energy flows processed through each main plant systems ( cement plant, carbon capture unit, CO 2 ...

list of equipments for a 300tpd cement grinding plant

list of equipments for a 300tpd cement grinding plant list of machine in 100 and for sell gold milling processing cost capacity chart 400 tpd 300 tpd 11 grinding. live chat; Projects_Cement Production Line,Cement. Export Achievements of Jiangsu Pengfei Group Co, Ltd No, Main Equipments of 300tpd cement plant, 200,000tpa pozzolana compound cement grinding plant. live chat; cement clinker ...

Cement Equipment In Cement Plant | AGICO Cement Plant ...

Its main function is to grind raw meal and cement clinker into an appropriate size to meet the qualified fineness. Industrial Dust Collector. The dust collector is the equipment used to solve the dust problem in cement production, which can not only ensure the production safety but also realize the rational use of resources. Conveyor. The industrial screw conveyor, belt type conveyor ...

CHAENGMining Equipment Suppliers

CHAENGMining Equipment Suppliers. Production Line. Products. Slag Grinding Plant. Slag powder is highperforming admixture for concrete in that it increases the concrete's ability to resist compression, tension, shear, and bending stresses. A major trend that characterizes the building material industry is to replace equal amount of cement ...

Leading Supplier of Cement Plant Equipments

AGICO is specialized in design and supply equipments for complete cement production lines of different scales, capacity from 300 to above 2500TPD,main equipments:Rotary Kiln, grinding equipment.

Cement Grinding Plant at Best Price in India

The grinding plant at a cement factory is used to reduce the particle size distribution of various materials such as raw meal, fuel or clinker to set parameters. In a sense, a grinding plant uses energy (through milling) to create fineness and it is the production .

MAINTENANCE IN THE CEMENT INDUSTRY

Maintenance in the cement industry is one of the contributors to the production cost and represent typical 15 – 25 percent of total manufacturing expenditure. Many companies have tried to use standard production methods to control maintenance costs.

Cement Plant, Cement Equipment | Cement Plant Manufacturer ...

Cement plant is necessary for cement production, mainly consist of a series of cement equipment apply for preparation of cement raw materials, clinker production, and finished cement production, such as cement mill, cement crusher, rotary kiln, cement roller press, cement dryer, clinker cooler, cement silo, and related cement plant equipment.

cement grinding station equipment supplier

Leading Supplier of Cement Plant Equipments Rotary Kiln. AGICO is specialized in design and supplies equipments for complete cement production lines of different scales, capacity from 300 to above 2500TPD; Main equipments include: rotary kiln, grinding equipment (ball mill and vertical mill), crusher(Jaw Crusher, Impact Crusher, Hammer Crusher), cooler (Rotary Cooler), preheater .

Latest Posts

- خام الحديد والمنغنيز في تجهيز الفحم في روسيا

- بيع المحمول محطم ملموسة

- إنتاج الأسمنت والرمل في إندونيسيا

- معدات تجهيز خام التيتانيوم

- كسارة خاصة للبيع

- كينيا مطحنة الصانع

- التوابل الصناعية الطاحن

- المواد الخام أو البنتونيت

- تركيب كسارات مخروط SBM في الهند

- كم كنت المسؤول عن كسر الحجر الجيري من المحجر

- سنديان و محطم

- نهر الرمال الرمال الاصطناعية

- حساب طحن وسائل الإعلام المستخدمة في إنتاج الأسمنت مطحنة الكرة

- الكندي الذهب شاكر

- الأبحاث المتعلقة ب رافعات الميناء رافعة البوابة

- Jaw Stone Crusher For Sale In South Africa

- Denver Fire Clay Company

- Iral Classifier Vibrating Feeder Ls Sand Washing Machine

- Sand Washers Images Video

- Asphalt Plant For Sale Used Mobil

- Mill Used In Crushing

- Gravel Quarry In Ethiopia Pdf

- Howhow To Mine Phosphate

- Used Precast And Factory Equipment For Sale

- European Vertical Axis Scrap Crushers

- Albania Standard For Stone Crusher

- Powder Hammer Mill Machine Sales In Malaysia

- Picturesof Equipment Used In Bau Ite Mining

- Crusher From What Material Made

- Gold Rock Crusher Plans Free Por Le