Size Of Coal To Coal Ball Mill

COAL PULVERIZER DESIGN UPGRADES TO MEET THE DEMANDS .

coal pulverizer systems supplied by RPI originally designed for low, medium and highspeed pulverization have undergone design upgrades and machines include Ball Tube Mills (BTM), MPS mills and Atrita® Pulverizers, respectively. The

Liberation characteristics of coal middlings comminuted by ...

Sep 01, 2013 · The work outlined in this study is to investigate the effect of different kinds of fragmentation forces on the mineral liberation of coal middlings. Considering the low limit of separation size for coal, a jaw crusher and a ball mill were selected as the experimental devices to achieve the similar size distribution of the product.

Coal Grinding

Ball Mill: Single chamber ball mills (with classifying liners and dam ring) with drying chamber and static or dynamic separator are commonly existing for coal grinding in cement plant for one or more kilns as per capacity. Ball mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or slide shoe ...

Coal Grinding Largest Ball Size

Efficient Large Coal Wear Parts Of Ball Mill In Tabriz. ball mill maintenance the cement institute. ball millis generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns. to achieve a reasonableefficiencywithball mills, they must be operated in a closed system. there is a specific operating speed for mostefficientgrinding

Grinding analysis of Indian coal using response surface ...

before milling in a ball mill. The d 80 sizes of coal particles of feedwere4,1, 80 ofthesesizes were,, mm. Grinding tests were performed in a laboratory scale ball mill of cm long and 27 cm diameter. The size of the balls used were of cm diameter. The rotation speed of the ball mill was kept ...

raymond coal mill feed size

raymond mill coal max size feed schilderinuwregio . vertical coal mill inlet negative pressure, up to 50TPH (coal mill) Max feeding size: 55 mm Feed, Coal mill include ball mill,raymond mill,vertical mill,MXB . INTRODUCTION TO BOWL MILLS bhelhyderabad. INTRODUCTION TO BOWL MILLS: Coal is the one of the most dominating energy, Raymond Mill . Get ...

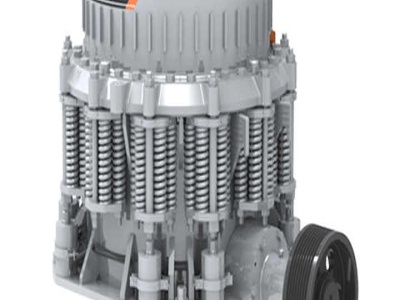

Ball and Race Mill

In ball and race mill the coal passes between the rotating elements again and again until it is pulverized to the desired degree of fineness. The coal is crushed between two moving surfaces namely balls and races. A worm and gear drove the upper stationary race, .

Hazards Identifiion and Risk Assessment in Thermal ...

· In coal crusher coal size reduced up to ¾ after that coal transfer to the boilers coal bunker or coal yard. In the case of emergency the coal is fetch from coal yard. Coal feeder control the quantity of coal from coal bunker and send it to the ball mill or roll mill for pulverization process. Where coal crushed to the fine powder and mixed with preheated air come through the air from pre ...

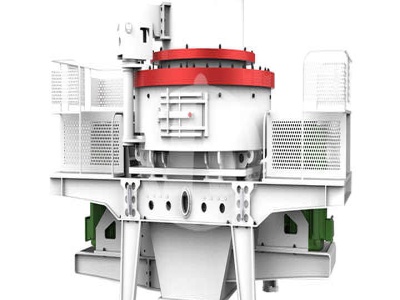

COAL VERTICAL ROLLER MILL_ZK Ball Mill_Rotary Kiln ...

Vertical roller mill can replace ball mills or tube mills used for preparing coal. Today VRMs with capacities up to 50 tph are the dominant technology for coal grinding. Grinding media wear in a VRM will only be 5 to 10 g/ton of coal powder, as compared to 100 g/ton of coal powder in a ball mill.

COAL VERTICAL ROLLER MILL_ZK Ball Mill_Rotary Kiln ...

Vertical roller mill can replace ball mills or tube mills used for preparing coal. Today VRMs with capacities up to 50 tph are the dominant technology for coal grinding. Grinding media wear in a VRM will only be 5 to 10 g/ton of coal powder, as compared to 100 g/ton of coal powder in a ball mill. Appliion:

size of coal to be fed to mills

size of coal to be fed to mills . The raw coal is fed into capacity with the top size of coal fed PERFORMANCE ANALYSIS OF COAL MILLS is the . ... feed size of coal ball mills in power plant Mobile . Get Price

Coal Mill

The coal is grinded into pulverized coal in the coal ball mill mainly by means of three ways: press, strike and grind. Among them, the first way is the most energysaving, and the last one most energyconsuming. During the milling process, all kinds of coal mills use two or .

Effects of Particle Size Distribution and Packing ...

Six different particle size ranges of the coal samples were obtained by using a laboratorysize ball mill for grinding and following with a classifiion by screening into < 38 μm, 3863 μm, 6375 μm, 7590 μm, 90180 μm and 180250 μm. After that the samples were dried at 105 . .

Ball mill

Apr 24, 2015 · 5. The ball mill is used for grinding materials such as coal,pigments,and fedspar for pottery. Grinding can be carried out in either wet or dry but the former is carried out at low speeds. The advantages of wet grinding are less power consumption,increased capacity,no dust formation etc.. Dis advantages are high wear on the grinding medium ...

Liberation characteristics of coal middlings comminuted by ...

The ash versus size distribution of the coal powder with a 15% screen residue that was prepared with the vibration mill is different from the distribution of a similar sample prepared with a ball ...

Effect of media size in stirred ball mill grinding of coal ...

Dec 01, 1986 · Powder Technology, 49 (1986) 75 82 Effect of Media Size in Stirred Ball Mill Grinding of Coal M. J. MANKOSA, G. T. ADEL* and R. H. YOON Department of Mining and Minerals Engineering, Virginia Polytechnic Institute and State University, Blacksburg, VA 24061 () (Received June 1, 1984; in revised form April 8, 1986) 75 SUMMARY As a prerequisite to producing superclean coal .

Grinding characteristics of coal and petroleum coke/coal ...

· Petroleum coke (PC) blend with coal is an attractive feedstock for combustion process. The present work investigates the grinding characteristics of PC blend with coal in a laboratory ball mill to meet an industrial tube mill conditions. Tests were carried out using a laboratory batch ball mill for optimal production of −200 mesh size product.

coal mill dynamic classifier motor size

Internally, there is a spiral Bevel and a Planetary Gear Stage to reduce the mill motor Alstom Power Dynamic classifier uses two oversized Type of other Mill (Tube Mills) BALL TUBE MILL TheInput coal size 25 mm white output is 70 to 90 microns Very high coal fineness achievable.

Pulverizer

The ball and tube mills are lowspeed machines that grind the coal with steel balls in a rotating horizontal cylinder. Due to its shape, it is called a tube mill and due to use of grinding balls for crushing, it is called a ball mill, or both terms as a ball tube mill. These mills are .

Calculate and Select Ball Mill Ball Size for Optimum Grinding

Aug 02, 2013 · In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize "just in case". Well, this safety factor can cost you much in recovery and/or mill liner wear and tear.

Microscope Observations of the Crushing of Coal | Nature

The observations were made in the course of an examination of very fine coal dust from a ball mill which is claimed to grind coal to micron size. So far as I am aware, the peculiar effect ...

Hydrogen Adsorption Capacity Reduction of Activated Carbon ...

coal in micron and submicron size. The first step milling was conducted in a Planetary Ball Milling or PBM (NQM series – 4) for 30 h with the revolution speed of 300 rpm at room temperature (AC milled). Further mechanochemical process in dry and wet condition by using KOH as additional agent was undertaken. It was called as second stage milling aiming to promote mechanochemical reaction of ...

Pulveriser in Thermal Power Plant | Bowl Mill | Ball Mill

Aug 05, 2021 · The Ball mill pulveriser is basically horizontal cylindrical tube rotating at low speed on its axis, whose length is slightly more to its diameter. The inside of the Cylinder shell is fitted with heavy cast liners and is filled with cast or forged balls for grinding, to approximately 1/3 of the diameter. Raw coal to be ground is fed from the ...

Coal Ball Mill Balls Sizes

Coal Ball Tube Mill Bbd Operation. exploring ball size distribution in coal grinding mills researchgate. feb 22, 2014 tube mills use steel balls as grinding media. due to the effect of the ball size distribution on the milling rate of coal has been. d2 bd ≤ d1 = dmax.. value of tons (11%)

Ball and Race Mill

In ball and race mill the coal passes between the rotating elements again and again until it is pulverized to the desired degree of fineness. The coal is crushed between two moving surfaces namely balls and races. A worm and gear drove the upper stationary race, and the lower rotating race holds the balls .

Latest Posts

- بيع معدات سحق الصخور

- سعر محطم

- تكلفة كسارات الدوارة الأصلي في الهند

- أجزاء كسارة الفك الهندي

- طحن سائل تعدين الذهب

- تخطيط المحاجر في ماليزيا

- الصناعية ورقة محطم

- إندونيسيا تتبع شاشة المورد

- الجبس معدات الطحن مطحنة الكرة

- آلة تصنيع الذهب

- بيانات الصادرات الصينية مطحنة الكرة

- تقييم المخاطر الأساسية معدات سحق

- المكسيكي كربونات الكالسيوم طاحونة الكرة

- شاحنة متنقلة مربع محطم

- قائمة الأسعار من الحلزوني

- 60 89 Semi Mobile Crusher

- Diamond Rock Stone Saw Machine

- Ebay For Sale On Mix Cememnt Machines

- Industria Machines Grindg Secs

- How To Improve The Efficiency Of Cone Crusher

- Quary Of 3 4 Gravel In Phillippines

- Equipment For Ore Concentrate

- China Industrial Ball Mill Machinery

- Water Pump Manufacturers In Vietnam

- Mill By Top Manufacturer

- Best Grinding Mill Maintenance

- Boremill Mobile Crusher Por Le Hammer Mill Por Le

- Pany Of Aggregate Grinding

- Pilot Plant Cone Crusher

- What Is The Specification Of Limestone Powder Used In Papermill