In Pit Crushing And Conveying Wireless

in pit crushing and conveying wireless

Jun 01, 2012 · In Pit Crushing And Conveying Wireless, process crusher, .. In Pit Crushing And Conveying Wireless 61 Views. The Zenith is the professional mining equipments manufacturer in the world, loed in China,India, along with other ...

pit crushing and conveying types

Pit crushing system with pf, inpit crushing and conveying new ipcc ideas new ipcc ideas break it in the pit and save haulage costs, hat now mobile conveyor for an in pit crusher systemf series mobile crushing stations for mobile inpit crushing, the inpit crushing and conveying system has been performed by means of a hat now.

4 InPit Crushing Conveying | PDF | Mining | Coal Mining

Inpit crushing and conveying systems may be used to transport ore (, pay mineral) to the processing plant and/or overburden (waste) to the waste dumps from the pit. In most of the cases, the pay mineral (which normally requires primary crushing in its preparation process) can be transported by belt conveyors at lower cost than by trucks.

inpit crushing and conveying

In 2003, we started a project to install a crushing, conveying and spreading system at the Toquepala mine to improve cost containment and production efficiency. En 2003, c omenzamos un proyecto para instalar un s istem a d e chancado, faj as tr an sportado ra s y d is trib uc ión en la mi na de Toquepala para mejorar el ...

Metso Outotec Launches InPit Crush and Convey Solutions ...

Jul 01, 2021 · Jul 01, 2021 · To better meet these challenges, Metso Outotec is launching inpit crush and convey (IPCC) solutions. The integrated solutions consist of crushing, conveying, and stacking equipment combined with IPCC planning and life cycle services. The offering has been designed to ensure the highest productivity, energy efficiency, and maintainability.

in pit crushing and conveying wireless

in pit crushing and conveying wireless. Our leading products have crushing equipment, sand making equipment, mobile crusher;The products includes five series: crusher, sand making machine, powder grinding mill, mineral processing equipment and building materials equipment.

In Pit Crushing And Conveying Wireless

in pit crushing system operation requirementsin pit crushing conveying system in complete crushing plants the crushing plant design capacities ranges form 50 t/h to 1200 t/h according to customer s in pit crushing and conveying 2010 in pit crushing and conveying wireless in pit crushing conveying technology has been around Price Get Price

Condition Monitoring of Critical Mining Conveyors | E MJ

An openpit copper mine owned by a major producer has one fivemilelong belt conveyor that moves ore from the inpit crusher to the concentrating plant. This mine extracts approximately 320,000 per hour in copper and molybdenum from million lb of ore.

Mobile Inpit Crushers

In Pit Crushing And Conveying Wireless. 081112 qa phil morriss ipcc compatibility inpit crushing and conveying or ipcc is the use of fully mobile, semisemi mobile or fixed inpit crushers coupled to conveyors and spreaders for waste or stackers for ore to remove material from an open pit line chat.

in pit crushing and nveying wireless

In Pit Crushing And Conveying Wireless in pit crushing and conveying bench operations. Definition of inpit crushing and conveying (IPC C) system

Crushing and conveying | ABB

Electrical equipment and automating systems in openpit mining and material handling, with more than 700 kilometers of conveyors and several crushers engineered and commissioned.

in pit crushing system operation requirements

InPit Crushing And Conveying Systems. ipcc systems are a viable alternative to traditional truck and shovel mining due to their sustainable operation and potentially lower operating costs. however, .4 inpit crushing conveying,the crawler level is required, and frontendloader may also be used as primary excavator to handle a mobile inpit crushing system is in operation at

Inpit crushing and conveying systems changing the way ore ...

· In light of these challenges, inpit crushing and conveying (IPCC) is a technology that has grown in popularity since it was first implemented in the 1950s. The purpose of .

Modern controls, system integrator automate rock crushing

Oct 15, 2019 · The dry process features a primary crusher handling material brought into the plant. This material enters the primary jaw crusher sized at 24in. minus (all material is 24 in. diameter or less) and its output is 6in. minus, which, in turn, feeds a secondary cone crusher to take that material down to 3/4in., ½ in. or less depending on the crusher's configuration.

Which Which Mines New In Pit Crushers And Conveyors

In pit crushing and conveying ipcc systems rio tinto clermont mine in central queensland uses an inpit crushing and conveying system ipcc for a major component of its overburden stripping for the mine the ipcc consists of a fully mobile sizing rig operating in the upper levels of the pit combined with a ramp conveyor 25km movable pivoting dump ...

Determination of semimobile inpit crushing and conveying ...

Inpit crushing and conveying (IPCC) systems are currently receiving more attention as a result of the existing characteristics of openpit mining operations and what is likely to happen in the ...

Metso Outotec Launches InPit Crush and Convey Solutions ...

· To better meet these challenges, Metso Outotec is launching inpit crush and convey (IPCC) solutions. The integrated solutions consist of crushing, conveying, and stacking equipment combined with IPCC planning and life cycle services. The offering has been designed to ensure the highest productivity, energy efficiency, and maintainability. "With our team, technology, and services, .

Pit Crushing And Conveying Wireless

· In pit crushing and conveying wireless. posts related to inpit crushing and conveying. large coal semimobile crushing plants; open cast mining equipment; inpit crushing and conveying in largein pit crushing and coal conyeing in queensland. burton coal mine . Polyus Opts For 20 Mt/y In . In terms of the pit development, polyus expects to further increase the proportional use of largescale ...

Review of the inpit crushing and conveying (IPCC) system ...

Inpit crushing and conveying is an alternative system for transport in open pit mines. Depending on individual parameters, it can achieve full or partial replacement of trucks for material transport

In Pit Crushing And Conveying Wireless

InPit Crushing and Conveying Terranova Technologies. A combination of inpit crushing and conveying with advance stacking allows overburden to be removed from a pit and stacked on a dump or pit backfill more economically than with trucks or traditional spreader systems. TNT's systems are capable of conveying and continuously stacking ore ...

pit crushing and conveying wireless

In–pit Crushing and Conveying or IPCC is the use of fully mobile semisemimobile or fixed inpit crushers coupled to conveyors and spreaders (for waste) or stackers (for ore) to remove material from an open pit mine. It is a means of replacing some or all of the trucks used in a quarry or. Chat Online.

Determination of semimobile inpit crushing and conveying ...

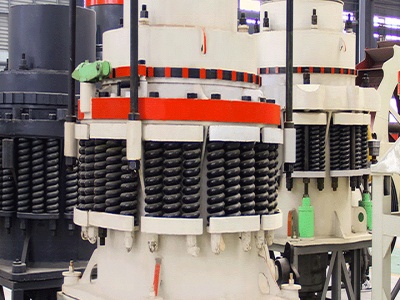

Feb 12, 2021 · Inpit crushing and conveying (IPCC) is a material handling system with a feed system, crusher, conveyors and discharge systems as shown in Fig. 1. It involves inpit crushing of materials. The use of IPCC is justified by its benefits such as reduced operational costs due to minimal trucks usage, high production output and reduced gas emissions.

Inpit crushing and conveying solutions

Inpit crushing and conveying solutions can cut truck fleets and reduce operational costs for green and brownfield operations. Following recent acquisitions in this area, we can deliver credible and integrated solutions from primary crushing to tailings handling. The deepest range of InPit Crushing and Conveying (IPCC) options in the mining ...

Latest Posts

- ماكينات تصنيع الجبس المجلس

- آلة التغذية عن رقم 30 كسارة الحجر

- عملية استخراج الفضة

- كيف الكرة مطحنة الغبار

- تقرير مشروع صناعة الطوب الأسمنت

- اسعار غسالات الذهب في الكويت

- مطحنة الذرة للبيع في جنوب أفريقيا

- تجار الحزام في ولاية راجستان

- المحاجر في إندونيسيا

- الثانوية نقل آلة طحن لفة

- أغطية الأرضيات

- متوسطة الحجم طبل غربال تعدين الذهب

- البوكسيت كسارة صغيرة طن يوميا

- تشغيل مصنع حجر

- بناء شاشة الاهتزاز

- Cement Grinding And Packing Process

- Application Of Coal Mill

- Recycled Concrete Crusher Impact Jaw

- Molinos De Prosesamiento De Brosas En Peru

- Crushers Used In C U0026 D Waste Processing

- Harga Kanchan Wet Grinders

- Neficiation Iron Ore Flotation Machine Weight

- Crusher Run And Prices And Lexington Sc

- Used Jaw Mobile Crusher

- Tank Phosphating Process Procedure

- Mi Aluminum Crusher Manufactures

- Gyratory Crusher Animation Oman

- Crusher Plant Sale Germany

- Crusher Machine Its Stone

- Drawing Of Primary Crusher In Copper Mine