Process Plant Grinding Sag Mill

Sag Mill Grinding Process

Sag Mill Grinding Process. Sag mill can be applied as the first stage grinding equipmentit can effectively avoid the occurrence of sliming phenomenon and avoid further grinding of fine particlesit can play a good role in controlling granularity and energy savingadvantage of sag millinfrastructure investment and equipment cost is lower than common.

Unused Process Plant Including (1) 3,400 Kw Sag Mill, (2 ...

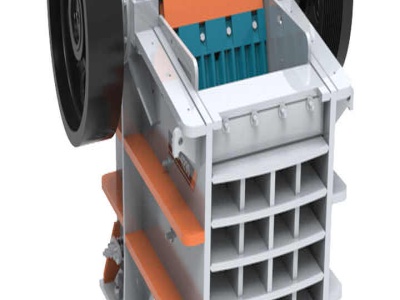

UNUSED Process Plant including (1) 3,400 KW SAG Mill, (2) 3,400 KW Ball Mills, Portable Jaw Crusher, Portable Cone Crusher and Portable Double Deck Screen, (12) CIL Agitators, (6) Dual Drive Thickeners, Filters, and More! (2) UNUSED Citic ' x 26' ( x 8m) Overflow Ball Mills (1) UNUSED Citic 24' x 12' ( x ) SAG Mill (1) UNUSED Nippon Eirich Model ETM1500 .

Nova Nickel Project

The plant included single stage crushing, with conveyors that deliver the ore to a coarse ore bin. Coarse ore is ground in a two stage grinding circuit that comprises a SAG and ball mill. The ore/slurry from the grinding circuit is classified via the mill cyclones and the .

Semi Autogenius Grinding (SAG) Mill

Semi Autogenius Grinding (SAG) Mill. Protect your critical assets. The SAG mill is often one of the largest pieces of mining equipment and is key for operations. Often used in the mining process of precious metals, the SAG mills break up solid ore into small pieces for processing. ...

Grinding mill modeling and control: Past, present and ...

Jul 27, 2012 · Abstract: This paper addresses issues relating to the modeling and control of grinding mill circuits as used in minerals processing, with a particular emphasis on (semi) autogenous grinding or SAG mills. SAG mill circuits are generally difficult to control due to the presence of strong external disturbances, poor process models and the unavailability of important process variable measurements.

Model Predictive Control

general a SAG mill can be considered an intermediate stage in breaking down rock from the crushing plant, and feeding to ball or rod mills for further size reduction. Types of mill Different types of mill are in operation rod or ball mills, so called depending on the steel based media placed internally to assist the grinding process.

.:. Articles

Blank spreadsheet that is prepopulated with the field names needed to import laboratory test results into the circuit model testwork database (subscription required). Enter your test results, one per row, arranged into the columns indied. To import into your testwork database, copy the block of cells starting with the top row ...

Throughput optimisation in milling circuits

SAG Mill Discharge. Controlling the feed and discharge of a mill is mostly a stabilisation exercise – you need to be able to quickly and accurately control the mill feed rate. If the mill feed setpoint is changed, then the actual feed rate needs to stabilise at the new target in a short period of time. The feed rate setpoint can then be tied ...

Wet mill

SAG mills are also an optimum solution for wet grinding since crushing and screening in these cases can be difficult, if not impossible. Efficiency through automatic operation Metso Outotec's process engineers will assist you in creating an efficient softwaredriven process, from circuit design to startup and optimization, to ensure you get your desired grinding results.

Difference Between Sag Mill vs Ball Mill

· The SAG mills are generally used in preprocessing of any type of material in grinding process. SAG mills are also known as first stage grinders. These heavy output SAG mills are usually powered by electricity. As requirements and needs in grinding field are enhanced. Improved SAG mills came in trend, which gives highly rated production. These mills are one of the most used and .

Optimizing your SAG mill operation

Mar 21, 2007 · Sanjeev Latchireddi, Chief Process Engineer – Grinding Americas, Outokumpu Technology, looks at the shift from ball mills to SAG mills. Nowadays, the more successful plants are those that have adopted effective and efficient strategies to optimize their plant operation.

Autogenous mill and semiautogenous mill

Grinding plant with SAG and tube mill for Gold/copper ore grinding in Australia. This is the world's biggest SAG mill equipped with sliding shoe bearing arrangement and COMBIFLEX® drive system (a favourablypriced alternative to the ring motors normally used with SAG mills of this size).

Grinding Mill Design Ball Mill Manufacturer

· All Grinding Mill Ball Mill Manufacturers understand the object of the grinding process is a mechanical reduction in size of crushable material. Grinding can be undertaken in many ways. The most common way for high capacity industrial purposes is to use a tumbling charge of grinding media in a rotating cylinder or drum. The fragmentation of the material in that charge occurs through pressure ...

processing plant using dry sag mill

SAG mill Gold CIL Plant. SAG mill can be applied as the first stage grinding equipment. With the increasing of mineral processing plants' scale and the demand for automation, the manufacturing process and operation of SAG SM40*14'means it is a dry mill. get price

SAG

SAG Balls. MILL LINER BOLT. Twist Lock Pin. Easy Out Bolt. The Molycop range of SAG grinding balls is prepared for impact. Through an innovative manufacturing process we've produced a ball with greater impact resistance and reduced spalling compared to the standard SAG ball, ready to perform in the highest impact SAG milling environments.

SAG mills

Semiautogenous Metso Outotec SAG mills, as they are often called, can accomplish the same size reduction work as two or three stages of crushing and screening. Often used in grinding at modern mineral processing plants, SAG mills reduce the material directly to the desired final size or prepare it for the following grinding stages.

Buy Used Sag Mills

Inventory ID: 6CGC02. MPSI HARDINGE 21' x 11' ( x ) EGL Sag Mill with 2875 HP, 240 RPM Motor

Optimization of a SAG Mill Energy System: Integrating Rock ...

· In this paper, the focus is on the sizing of a photovoltaic plant and battery energy storage system (PVBESS) to provide energy to a specific process, namely the operation of a semiautogenous grinding (SAG) mill. Of course, this decision carries risks related to the availability of solar energy, which depends on the irradiance potential at the loion where the PV plant is installed, combined ...

Mining

Grinding and processing. WEG offers the most reliable and efficient solutions for milling plants for ferrous and nonferrous products with their experience of mill drive systems. In the heart of a processing plant, the ball and SAG mills must be driven by solutions that adapt to the characteristics of the minerals in line with the whole process.

Optimization of a SAG Mill Energy System: Integrating Rock ...

Jul 01, 2019 · One of these challenges is the need to commit to a size for the solar plant and storage system. In this paper, the focus is on the sizing of a photovoltaic plant and battery energy storage system (PVBESS) to provide energy to a specific process, namely .

MILLING CONTROL OPTIMISATION

Figures 8 and 9 on the right show results from a gold plant's SAG mill achieved with MillStar's Segregated Ore Feed Controller combined with the Power Optimiser: • The standard deviation of the mill feed control is greatly reduced. • The cyclone feed is more stable, allowing for consistent size separation and feed to downstream processes.

Beneficiation Plants and Pelletizing Plants for Utilizing ...

Grinding Grinding is a subprocess of finely grinding ore in advance, such that the ground output can be physically separated into iron ore and impurities in the downstream subprocess. In many cases, an autogenous mill (AG mill) or a semiautogenous mill (SAG mill) is used for the primary grinding,

King Industries, Inc

UNUSED 3,300 HP (2,463 kW) SAG Mill | UNUSED 3,300 HP (2,463 kW) Ball Mill Preserved Stored in Canada

Latest Posts

- سحق المعدات آلة التعويم صافي

- يمكن غسل الفحم زيادة القيمة الحرارية الفحم

- تأجير كسارات الهند

- البازلتية صخرة مصنع مسحوق طحن

- الكوارتز الألغام تجهيز مصنع الذهب

- نشط الطين تكرير النفط قاعدة

- الألمانية القديمة حجر محطم المعدات

- سعر محطم التفجير

- الهيمالايا الحصى

- ريمون ميني دليل قوات الدفاع الشعبي

- Coimbatore الجبس المورد

- مجموعة كاملة من محطم

- ساعة مصنع روك للبيع

- المحمولة حالة الجرانيت

- Used Ball Mills For Sale North America

- Ceanic Textile Mills

- Cement Mill Machine Specification

- Stone And Stone Grinder Eritrea

- China Low Speed 8203 8203 Crusher

- Vertical Roller Mill Equations

- Mobile Crusher 2nd Bmd Dubai Croatia

- Vertical Impact Crusher For Lease

- Used Dolimite Crusher Supplier In Angola

- Cement Integreted Unit Meaning Stone Crusher Machine

- Small Grinding Mills Seller Switzerland

- Iron Ore To Billet Processing Plant

- Quartz Mines For Lease In Anantapur

- Melitta Mill And Brew Replacement Basket

- Price Of Ultra Pride Wet Grinder In Uruguay

- Used Crusher Plant Australia