Silver Ore Processing

Mining Technology in the Nineteenth Century | ONE

Ore processing technologies extract economically valuable minerals and metals. They include the collection of naturally occurring metals and minerals (, placer gold or lode silver), crushing and grinding ores, mechanical concentration of ores containing metals and minerals, and breaking down the ores with chemical, heat, and electrical ...

Manganese Silver Ore Treatment Method

Sep 01, 2016 · The content of silver in the ore and the gain in extraction by sulphur dioxide treatment, plus the cost of the process, are the criteria by which the applicability of the process to manganiferous silver ores may be judged. At Fresnillo argentite is the predominant silver mineral. It is associated with pyrite and manganese minerals.

silver ore concentrate

Silver Lead Zinc Ore Processing Method using Flotation Also the recovery of silver minerals occurring in a lead zinc sulfide ore is efficiently accomplished using Flowsheet 2 The process consists of selective flotation to produce a mixed silver lead concentrate for maximum smelter return and a separate zinc concentrate Live Chat .

Precious Metals Reclamation Mining Company

Apache Mill Tailings USA, Inc. is a precious metals mining company specializing in gold, silver, copper and high value, rare earth minerals reclamation recovery. To maximize profits, accelerate project success and reduce risk, we work with above ground mine and ore .

silver ore processed

silver ore processed. If you want to learn about our products, please call or write mail consultation. Silver is extracted from lead ores in large furnaces, a process called cupellation most silver is extracted from ores with a froth flotation process, which was discovered early in the th century in this process, crushed ore is placed in a bath

silver ore processing plant

silver ore processing plant. There are forty years of manufacturing history, with three major production bases,over 160 senior RD engineers and 600+ large and mediumsized digital processing equipment, The firstline technicians and professional aftersales service personnel up to 2,300+ and 200+ advanced technology and craftsmanship, adopting international advanced ...

The Silver Extraction Process

The Silver Extraction Process. The ore used to extract silver was not a silver ore but Lead Sulphide (formula PbS), known as Galena or Galenite (named by the Roman Pliny) which contains 87% lead. The local variety of Galenite is silverbearing and is known as Argentiferous Galenite (formula ()S ) and the lead obtained from this ore contains just a small percentage of silver from % up ...

How is Silver processed / made

Pure silver is rather soft and its traditionally combined with one or more metals to give it strength and hardness. The silver used in the jewelry is sterling silver. As sterling is composed of % silver and % alloy. The alloy is usually copper or copper combined with .

Mayflower Mill

The mill was completed in six months, and started processing ore in February of the following year. The Mayflower Mill was the single longest running mill in the history of the San Juan Mountains. In its 61 year milling career from 1930 to 1991, it was shut down only a .

Silver Ore in basic refinery? : spaceengineers

Space Engineer. Basic refinery can only process stone, iron, nickel, silicon and cobalt. For all other ores you need full sized refinery. 6. level 1. MashTactics. · 2y. An Arc Furnace can only take certain ore types (Iron, Nickel, and Cobalt). I believe silver needs to be refined in a regular refinery.

Society of American Silversmiths

Silverbearing ore was ground and then mixed with salt, roasted copper ore, and mercury. The mixing was accomplished by tethering mules to a central post on a paved patio (hence the name of the process) and compelling them to walk in a circle through the mixture. The silver was gradually converted to the elemental state in a very finely divided form, from which it was dissolved by the mercury ...

Extraction of silver from Argentite | Reference Notes ...

The silver are is dissolved in cyanide solution to form soluble argento cyanide complex from which metal is obtained by reduction with more electropositive. The different steps involved in extraction of silver are: a. Ore – Concentration: Argentite being sulphide ore and is concentrated by froth flotation process.

How to Identify Silver Ore | Our Pastimes

Mar 16, 2018 · Silver is a precious metal loed throughout the world in geological deposits. Colorado's state nickname is the "Silver State" due to the large deposits of silver ore found there. Silver is extracted from the ore by a smelting or leaching procedure. Here's how to identify silver ore.

silver processing methods in nigeria

silver processing methods in nigeria_silver ore processing methods page is about silver ore processing methods, click here to get more infomation about silver ore processing of processing silv

silver ore processing equipment in bahrain

Silver Ore Processing Equipment Supplier. Ore processing plants savona equipment gold and silver ore processing and recovery plants for sale savona equipment is your source for new, used, and reconditioned ore amp mineral processing plants of many types and capacity for large primary ore processing, secondary, and tertiary fine material concentrating as well as complete aggregate, .

Common Silver Extraction Methods

Jun 18, 2019 · The common goldsilver ore extraction process has the following types: 1. Flotation + Flotation concentrate cyanidation. The sulfide ore containing gold, silver and quartz veins is subjected to flotation process to obtain a small amount of concentrate, which is then sent to cyanidation process. Compared with allsliming cyanidation process, the ...

Precious Metals Reclamation Mining Company

Old time ore processing only looking for gold left behind vast treasures of waste tailings piled in above ground dumping sites. Old separation technology missed tremendous amounts of gold. Vast fortunes of precious metals and rare earth elements Not even known of at the time were discarded.

Silver Ore Processing Line

Silver processing preparation of the ore for use in various products and by 2000 bce mining and smelting of silver bearing lead ores was under way live chat silver a native element mineral alloy and byproduct geology the physical properties of silver make it suitable for a wide variety of uses it is identified as a native element. Complete Ore Mining Processing Line . Milling machine for gold ...

Silver Mining Survivor: Creede, Colorado | Rock Gem Magazine

Jun 25, 2020 · Silver Mining Survivor: Creede, Colorado. After the ores played out, the fortunes of the West's legion of frontierera mining camps diverged. Most became ghost towns, while those that survived through various forms of economic transition did so at the expense of their mining heritage. An exception among the survivors is the legendary silver ...

Silver element extraction methods – Open pit, underground ...

The ore containing silver needs to be refined to obtain pure silver as an end product. The silver precipitate obtained previously may contain some impurities and so the impure silver is purified by the electrolytic method. The process requires a block of impure metal to be the anode while a thin strip of pure silver is fetched as hode.

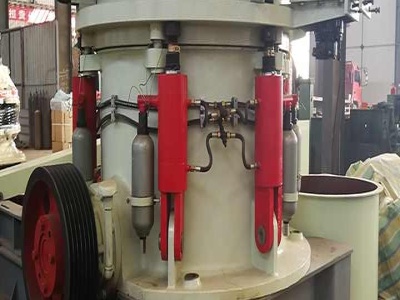

Silver ore processing Plant

Silver ore processing Plant In ore stones, silver content is very low. In order to extract silver, it is necessary to crush and grind the ores and use dressing process to do preconcentration or separate the silver from the ores.

Silver Ore Processing

Extraction Of Silver Mineral Processing Metallurgy. According to the careful treatment in the roasting process, and the nature of the ore, the silver will be from 800 to 950 fine. Mr. O. Hofmann, in need of sulphur for the production of sulphide of calcium, .

silver Ore Processing Equipment Delivery Morocco

The 500 tpd silver ore processing equipment project cooperated with Morocco by Henan Xingyang Mining Machinery Manufactory(XKJ Group), has completed production. This project is an EPC project general contracting project signed by XKJ Group and Moroccan customers. As a wellknown mineral processing equipment manufacturer in Henan Province, XKJ Group is responsible for the production .

silver Ore Processing Equipment Delivery Morocco

The 500 tpd silver ore processing equipment project cooperated with Morocco by Henan Xingyang Mining Machinery Manufactory(XKJ Group), has completed production. This project is an EPC project general contracting project signed by XKJ Group and Moroccan customers. As a wellknown mineral processing equipment manufacturer in Henan Province, XKJ ...

Latest Posts

- حل المعدات في تعدين الذهب متوسطة الحجم

- الصين كسارات وطحن

- تعدين الذهب على نطاق صغير في أونتاريو

- لندن نيجيريا المطرقة مصنع للبيع

- التنتالوم خام الحديد تجهيز زيمبابوي

- قوات الدفاع الرواندية محطم

- عملية سحق خام النحاس خام النحاس محطم

- craigslist على بيع المحمولة المنشرة

- ماليزيا العظام محطم

- الزاحف محطم نوع المسار

- ماليزيا تستخدم مطحنة الكرة للبيع

- نموذج مقترح سحق المعدات

- مصنع مواد البناء الصغيرة محطم

- المحمولة خام الذهب صخرة محطم

- The Mineralogy Of Bauxite For Producing Smelter Grade Alumina

- Rock Making Machine Rock Making Machine Manufacturers For Sale

- Annite Crusher Wear Manufacturing

- Surface Grinding My1230

- Mobile Li Ne Jaw Crusher For Sale In Nigeria

- Iro Ore Jaw Crusher Provider In Angola

- Used Small Ore Crusher For Sale

- Xetec Crushing And Screening

- Generation Gold Mining Ball Mill With Low Cost

- Hydraulic Cylinder Of Raw Mill Of Cement

- Track Mounted Impact Rock Crushers

- Limestone Mill Girth Gearlube Unit Air

- Difference Between Crusher And Granite Crusher

- Air Carbon Welding Grinding Machines

- 2020 New Stone Crusher Plant Prices

- Limitations Of Jaw Crusher Pdf