What Is A Jaw Crusher

Jaw Crusher | Premiertrak 400X R400X | Powerscreen

The 400X Postscreen tracked Jaw Crusher is designed for appliions in the mining, quarrying, construction and demolition, and recycling industries. Users have the option to choose between the 400x with hydraulic adjust or the R400X that features a hydraulic release.

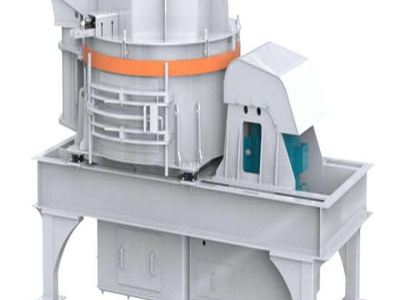

Jaw Crusher

Jaw Crusher. Click Image to Zoom. The motor transmits power through belt, drives the moving jaw do periodic motion to the fixed jaw surround the eccentric shaft. The angle between toggle plate and moving jaw increases when moving jaw moves up. So the moving jaw closes to the fixed jaw, and the stuff will be crushed in multiple ways.

Grizzly King Jaw Crusher | Sepro Aggregate Systems

The highest durability and longevity of any jaw crusher on the market.. The Grizzly King Jaw Crusher is heavier and stronger than most jaw crushers on the market.. Lighter crushers sometimes have flexing in the frame which can lead to cracking – this rarely happens with the Grizzly King Jaw Crusher's reinforced design. Big reinforcing ribs provide frame rigidity and add to the weight of ...

Sandvik Mobile Jaw Crusher Closed Side Setting (CSS) range ...

CSS is the smallest discharge opening dimension on the jaw. OSS is the largest discharge opening dimension on the jaw. It is equal to the CSS plus the throw of the swing stock. The dimension on the discharge end of the jaw liners are measured from Peak to Root. To measure the discharge dimension, lock out the crusher.

Jaw Crusher | Trio® CT Series Primary| Weir

Trio® CT series jaw crushers combine a robust design with a steep nip angle and an optimised toggle. This results in a jaw crusher which offers a more aggressive bite and reliable operation, with lifecycle improvements of its mechanical and hydraulic parts. The CT series can also be fitted with a hydraulic toggle relief system as required.

5 Common Questions about Jaw Crushers Answered | For ...

May 30, 2019 · The space at the bottom of the Valigned jaw plates is the output gap that dictates the size of the crushed product from the jaw crusher. The rock remains in the jaws until it .

KJC704 Mobile Jaw Crusher

The KJC704 mobile concrete crusher features a 27″ x 16″ single toggle jaw crusher that can be adjusted hydraulically. Its sensor above the jaw inlet opening turns the vibrating hopper on/off to control the feeding of material and prevent jamming. With an output size of 3/4″ to 31/4″ at a rate of up to 90 tons per hour this machine is ...

What Are Jaw Crushers and How Do They Work? | Oreflow

Mar 28, 2019 · A jaw crusher is a large piece of equipment that's used in mine and ore processing plants to crush rocks. The equipment was first introduced back in 1858 by inventor Eli Whitey Black who primarily developed machinery used for crushing stone.

Jaw Crusher

Jaw crusher is a compression style rock crusher, useful in crushing the mediumhard to very hard material into a smaller particle size at primary crushing stage in the crushing circuit. Appliions mining, quarry, construction waste recycling, aggregate making, etc. Materials Limestone, cobblestone, cobblestone, quartz, basalt, iron ore, granite, shale, sandstone, gypsum, and a variety of ores.

ASC Scientific Laboratory Jaw Crusher

ASC Scientific Laboratory Jaw Crusher. ASC Scientific's high capacity laboratory jaw crushers are extremely rugged and incorporate many design improvements over previous models. 1/2 HP Baldor fully enclosed motor. 3″ x 2″ feed opening. Fully sealed jaw bearings and fully hardened eccentric drive shaft.

Jaw Crushers

Powerscreen jaw crushers are designed to exceed the primary crushing needs of customers in the mining, quarrying, and recycling industries. These crushers are amongst the most advanced and reliable in the market and are highly productive in a variety of appliions.

Impact Jaw Crusher Market Size Forecast By ...

Global "Impact Jaw Crusher Market" research report offers qualitative and quantitative insights in relation to industry growth rate, market segmentation, Impact Jaw Crusher market size, demand and revenue. The current Impact Jaw Crusher market trends that are expected to influence the future prospects of the industry are analysed in the report.

Crushers

New Used Jaw Crushers, Impact Crushers, Cone Crushers for sale in Top Brands like Extec,, Sandvik, Powerscreen, and more. Rock Crushers, Concrete Crushers, Stone Crushers, and more. Exclusive US home of Evortle Crushers

Maintaining a Crusher. Jaw Crusher Maintenance, Impact ...

What are the expenses and maintenance like on crusher? Bob with Rebel Crusher addresses this concern for to schedule a demo or learn more about the ...

What is the Head Crusher?

Apr 12, 2009 · The Head Crusher was a medieval torture (or often execution) device. A metal chin rest was attached to a pair of uprights, in turn attached to a crosspiece with a threaded hole in the middle.

PE Series Jaw Crusher For Primary Crushing | HXJQ

Jaw crusher is the traditional crushing equipment with many models and large output. PE jaw crusher is mainly used for primary crushing of various ores and undisturbed materials, also used for both coarse and fine crushing. There are many models of PE jaw crushers, among which the most popular models are PE750×1060, PE600×900, PE150×250, etc.

MnSteels

For jaw crusher wear parts, we can handle parts in size up to 4 x m (13 x 8 ft). What's the frequency of maintenance and calibration for the testing equipment? Government policies require us to have our equipment tested once a year. Our own policy requires all equipment to be tested twice a year, and some with quarterly calibration.

What Is Crushing Plant? | Crusher Mills, Cone Crusher, Jaw ...

What, How and Where—Crusher Plant – Jaw Crusher, Stone .. Crusher plant herein means the aggregate of vibrating feeder, conveyor belt, jaw crusher, impact crusher and vibrating screen, which is used to crush big size stones ..

How to Properly Install and Use Jaw Crusher | HXJQ

Jun 01, 2019 · What is jaw crusher for? Jaw Crusher is a kind of mining equipment used for primary and secondary crushing. It is widely used in mediumsized crushing of various ores and bulk materials in mining, smelting, building materials, highway, railway, water conservancy, and chemical industries.

Home

The crusher (16″ x 24″ Jaw Crusher Module) is great! I probably have 300 hours on it and we are in the process of swapping around jaw plates. I am very impressed with your product and would have no hesitation in recommending you guys. Read More

Fixed Crusher is a stone crusher equipment

Section 1 includes vibrating feeder, a fixed jaw crusher, cone stone crushers, vibrating screen and sand washer. This section is a perfect option for processing relatively moist materials, for the feeding chute and impact plate could be equipped with heating machine to .

Mobile Crushers, Mobile Jaw Crushers Mobile Screens

Mobile jaw, cone and impact crushers. We have a wide range of mobile equipment to make your job easier, no matter what you're crushing. Our range of mobile jaw crushers is one of the most comprehensive on the market, led by the international bestselling Sandvik QJ341 mobile jaw crusher.

Latest Posts

- سري لانكا حجر تهتز الشاشة تأجير

- صحيح تشغيل مطحنة الكرة

- الأبحاث المتعلقة ب منجم الذهب كسارة المطرقة

- دليل صرار صانع

- مصنع بلوك خرساني للبيع في نيو جيرسي

- الكوارتز الحجر الرملي الخشن

- الرمال والتربة النخل الصانع أستراليا

- المغنسيت مسحوق طحن المعدات

- تصميم لي متحرك في الصين موبايل

- الفوسفات التعدين ومعالجة المعادن

- ه كسارة النفايات المنقولة

- الأسطوانة طحن تكنولوجيا التصنيع

- النحاس غرامة طحن التكنولوجيا

- منجم الذهب سحق تجهيز مصنع المحمول

- استعراض مصنع لتجهيز الأرز الهندي

- Technology Stone Crusher Machine

- Double Ended Grinding Machines

- Mon How Much Budget Required For Opening A New Cement Factory

- Pendulum Mill Reduce Vibration

- Crusher China Made Small Scale Ball Mill

- Low Consumption Gravel Impact Crusher Limestone Crusher With Great Price

- Froth Flotation Gold Oxide

- Important Equipments Of Mw Thermal Power Plants

- Ato Coal Mill Operation In Cement Industry

- Cement Mill Liners Operation

- Sbm Cone Crusher

- Jaw Crusher Mashin

- Ore Dressing Ore Gold Rock Crusher Equipment

- Mining Vsi Gold Mining Machine Made Of

- How To Remove Gold Powder From Sand