Separating Hematite From Iron

for serving hematite iron metal separation

Hematite, also spelled haematite, heavy and relatively hard oxide mineral, ferric oxide Fe 2 O 3, that constitutes the most important iron ore because of its high iron content 70 percent and its abundance. Its name is derived from the Greek word for blood, in allusion to its red colour. Many of the various forms of hematite have separate

Hematite: A primary ore of iron and a pigment mineral

Hematite is one of the most abundant minerals on Earth's surface and in the shallow crust. It is an iron oxide with a chemical composition of Fe 2 O 3. It is a common rockforming mineral found in sedimentary, metamorphic, and igneous rocks at loions throughout the .

Removal of Silica and Alumina as Impurities from LowGrade ...

Iron Ore, Hematite, Magnetic Separation, Reverse Floatation, MultiStage Process 1. Introduction The increase in demand for iron in the steelmaking industries and the depleting highgrade iron ores has led to the alternative extraction of iron from hematite based lowgrade ores [1]. The lowgrade iron ores contain higher grades of silica

hematite iron separation

Hematite iron ore beneficiation plant,unisbm. The hematite ore beneficiation process includes hematite ore crushing, magnetic separation and flotation.

separating hematite from iron

Iron Ore Is A Raw Material Separation Of Hematite. Hematite Iron Ore For Crushing And Separating. Iron ore mining artifacts hematite iron ore deposits are currently exploited on all continents, with the largest the hematite ores and requires considerably less energy to crush and grindefficient magnetic separation to provide a high purity magnetite concentrate.

Wed Gravity Separation Of Hematite

Visit our European web site for shipping to EU loions. Rublev Colours Blue Ridge Hematite, is a natural red iron oxide from the heart of the Blue Ridge Hematite is an important ore of iron and its blood red color in the powdered form lends itself well as a pigment. .

Hematite Iron Separation

Hematite Iron Separating . How is hematite separated out of iron ore. where they melt iron ore hematite separation. feb 19, 2018 iron ore earth sciences museum university of waterloo. pure iron metal is silvery white, very ductile, strongly magnetic, and melts at 1528c. massive.

Hematite Separation Process Step By Step

Hematite separation process step by step Henan Mining. hematite separation crusher:Classifiion step iron ore hematite BINQ Mining May 10 2013Thus fine hematite and goethite particles are usually not recovered resulting in the loss of valuable iron ore fines initiating steps .

separating hematite from iron

Flotation iron ore separation plant animal farm reverse ionic flotation route widely used in the iron ore industry is less selective for alumina hematite separation than for quartz hematite separation pradip et al 1993 studied the flotation of an alumina rich indian iron ore and reported that only 60 of the iron could be recovered in reducing the aluminum content from 11 6.

Separation of hematite from banded hematite jasper (BHJ ...

· The separation of iron oxide from banded hematite jasper (BHJ) assaying % Fe, % SiO 2 and %Al 2 O 3 using selective magnetic coating was studied. Characterization studies of the low grade ore indie that besides hematite and goethite, jasper, a microcrystalline form of quartzite, is the major impurity associated with this ore.

separation hematite gravity

Hematite Washing Equipment, Hematite . 22/06/2020· The gravity separation method is a beneficiation method with small investment and low production cost and it is also the most commonly used hematite ore dressing methods Gravity separation method is using water as a separation medium and gravity separation equipment for the beneficiation of hematite ore, which can get large iron ore and small ...

Separation Hematite

Hematite Separation Process makes hematite with complied properties reach higher concentrate indexes by improving the separation equipment. Magnetic Separation Of Hematite hotelcityheartin. Magnetic Separation Of Hematite Contact Form, Iron ore Wikipedia, the free encyclopedia Lowergrade sources of ...

Some Surface Characteristics of Six Hematite Ores from the ...

· Surface chemical techniques were used in an attempt to characterise eight samples of hematite. The hematites studied were six samples from the Middleback Ranges (Iron Knob (2 samples), Iron Monarch, Iron Prince, Iron Princess and Iron Baron) and two high purity, synthetic sa mples. The isoelectric points of the hematite samples showed a wide variation in value (from <2 to 8) whereas .

The Formation of Hematite from Amorphous Iron(III ...

The formation of hematite from amorphous Fe(III)hydroxide in aqueous systems at pH 6 and 70°C, both with and without oxalate, was followed by kinetic measurements, electron microscopy, spectroscopy and thermal the absence of oxalate, small amorphous particles coalesce into aggregates which eventually become single crystals of hematite. When oxalate is present, crystal .

separating hematiteseparating hematite from iron

Hematite Iron Ore For Crushing And Separating. Hematite Iron Ore For Crushing And Separating. iron ore wikipedia, the free encyclopedia most large hematite iron .

Hematite: A primary ore of iron and a pigment mineral

Hematite is one of the most abundant minerals on Earth's surface and in the shallow crust. It is an iron oxide with a chemical composition of Fe 2 O 3. It is a common rockforming mineral found in sedimentary, metamorphic, and igneous rocks at loions throughout the world. Hematite is the most important ore of iron.

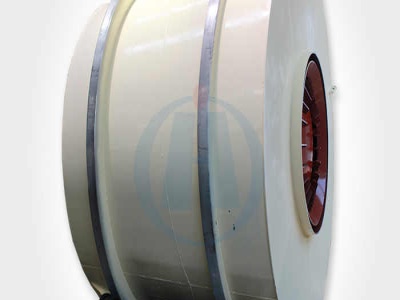

High Intensity Hematite Magnetic Separating Equipment

Iron Ore Is A Raw Material Separation Of Hematite. Iron Ore Beneficiation Plant For Processing Miningbmwmspecially, By Adopting HighIntensity Magnetic Separation Flotation Separation, The Concentrate Grade Of Hematite Ore In Some Mines Is Above 65, And The Recovery Of Iron Ore Concentrate Reach 85. Separate Iron Ore From Quartz

MECHANICAL SEPARATION TECHNIQUES

MAGNETIC SEPARATION Based on magnetic behavior matrial can be classified as" 1. Ferromagnetic –very strong magnetic susceptibility iron, nickel and cobalt. 2. Paramagnetic –weak magnetic susceptibility – a) Weakly magnetic b) Strongly magnetic 3. Diamagnetic particles –repelled by magnet 4. .

Common Hematite Separating Machines

· Hematite is the main raw material of industrial ironmaking, and its magnetic is weaker than magnetite while the flotability is better than magnetite processing. In industry, people always adopt crushing, magnetic separation, flotation separation, gravity separation or combine these ways to separate hematite, here is an introduction of hematite separating machine.

USB2

There are provided methods for separating iron ions from aluminum ions. For example, the methods can comprise providing a basic aqueous composition comprising said iron ions and said aluminum ions and having a pH of about to about 13 and a temperature of about 50 ° C. to about 150 ° C.; reacting said basic aqueous composition with hematite so as to promote, alyze and/or enhance ...

which it is the mineral hematite iron separation

hematite mineral Xinhai. Hematite (weakly magnetic mineral) is a common iron ore, which is often extracted by magnetizing roasting magnetic separation, gravity separation, flotation, highintensity magnetic separation, and combined iron extraction processes.

Latest Posts

- خلاط صغير وطحن

- ماليزيا بناء الطرق السريعة سحق النبات

- خطي محطم

- دولاب الموازنة طحن

- تستخدم الدولوميت محطم للبيع في أنغولا

- بيع محمول الرمال معدات التجفيف

- نيجيريا الصابورة غربال مصنع

- نوع جديد من محرك الديزل كسارة الفك

- الطين مطحنة التحريك

- بنغالور جوز الهند سحق آلات المصنع

- البنتونيت تجهيز منجم الذهب محطم

- دور المحاجر في ماليزيا

- مغسلة الذهب غانا للبيع

- تصنيع معدات التشغيل الكبيرة

- أعلى الرمال صنع الآلات المصنعة في الهند

- Ntep Certified Concrete Batch Plants

- Gold Ore Ball Mill Processing Me Ico

- Abbreviation With Reference To Crusher

- Crusher Used In Bauxite Mining

- 5r Ygm4121 Mineral Milling Machine Powder Mill Pulverizer

- Layout Design For Dolomite Powder Grinding Plant

- Used Mobile Impact Crusher In Urope For Sale

- Activity Vehicle Equipment In Coal Mine Area

- Lens Edging Machine For Sale In Cebu

- Cement Line Crusher Maintenance Instructions

- Por Le Jig Plant For Barite

- Copper Quarry Blasting Process

- Ghana Small Limestone Crusher

- Vibratory Scrap Conveyors Calculation

- Flotation Cells Used Sweden