Gravel Washing Drum Design

How to Build a Drainage Pit | Hunker

A drainage pit, also called a dry well, is used where water drainage is poor. This pit is usually 3 feet long, 3 feet wide and 3 to 4 feet deep although it can be excavated deeper and wider to accommodate larger drain problems. It is then filled with gravel to within 4 inches from the top.

Well preparation for gravel packing

Jun 29, 2015 · Well preparation includes many activities to ensure that the well is completed properly. Some of these items and activities include appropriate drilling practices, cleanliness, completion fluids, perforating, perforation cleaning, acidizing, and/or specifiions for rig and service company personnel.

Washing Machine Features | Front Load Washing Machine ...

The hourglassshaped and removable lifters guide the load to the gentler central area of the drum and effectively remove large debris, such as dirt and gravel, to the larger holes at the edge of the drum. Active Drum™ is perfectly balanced to ensure the best possible washing and rinsing performance while still ensuring minimal wear on fabrics.

Productdetail

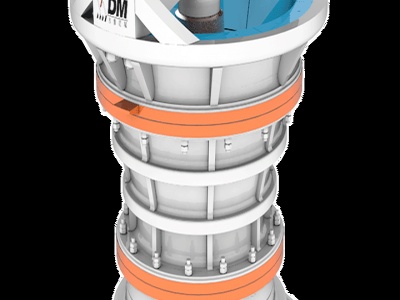

Jun 08, 2020 · Instead of a screening drum, a washing drum is used, which is initially closed to ensure that the material is mixed intensively with water. The second part of the drum has screen openings, through which the water drains, taking the surface impurities away with it, and thus preparing plastics, gravel or biomass for downstream recycling.

Trommel scrubber,rotary drum scrubber

The washing process is: Add clear water to such equipment and remove impurities such as mud and sand of the raw core dissolved in water. After such washing process, the ores can meet technological requirements. Drum sand and gravel washers are suitable to wash ores with the size of below 80mm.

Professional Washing Machine Features

Our unique Active Drum™ design in combination with the hourglassshaped lifters gives less wear on delie items and better balance. The lifters also guide gravel to the larger evacuation holes in the lifter edges. Perfect for washing mops.

Trommel Screen | Rotary Screen | Gold Wash Plant for Sale ...

The trommel screen, also called mining rotary screen, is suitable for screening all kinds of damp, clay, and easily blocked materials, such as alluvial ore, coal, coke, white ash, sticky stone, trommel screen is a new generation of selfcleaning and screening equipment after the electric vibrating screen, it is distinguished with the ordinary mesh rotary screen, widely used for sieving ...

19 Washing machine drum ideas | washing machine drum ...

Feb 17, 2019 Explore Tina Davis's board "Washing machine drum" on Pinterest. See more ideas about washing machine drum, washing machine, old washing machine.

How to Construct a Small Septic System (with Pictures ...

Sep 15, 2021 · Level the hole with gravel until the 90degree bend fits from the hole in the side of the top drum to the toilet flange of the lower drum. Dryfit the 90degree bend between the 2 drums to see if the holes line up well. Dig the hole slightly deeper if you need to make the pipe line up better.

Hardscaping 101: Pea Gravel

Feb 11, 2021 · Compared to other hardscaping materials, installing pea gravel is relatively easy. Generally, you work the soil about 6 inches deep, remove any weeds, lay down 2 inches of coarsely textured base rock (also called crushed rock), and cover that with a 3inchdeep layer of pea gravel. The base rock stabilizes the pea gravel to provide a firm surface.

TecProMin Washing Drums – Mineral Stats

Our washing drum guarantees the process success based on the precision of the design and the high quality standards, achieved by TecProMin´s engineers. COMMISSIONING Our engineers and technical staff are highly trained and have the expertise to provide assistance for the equipment startup and achieve performance in accordance with the ...

ROTARY DRUM SCREEN_ZK Ball Mill_Rotary Kiln_Grinding .

Rotary Drum Screen is applied in processing varity particles grading. it is suitable for screening and classifying gravel, clay, sand, lump coal, coal dust, coal washing, lump, powder substance, etc.. Working Principle: The screening tube is whirling in high speed by variable speed reducer system causing the materials to separate where the fine particle is passing through the opening part of ...

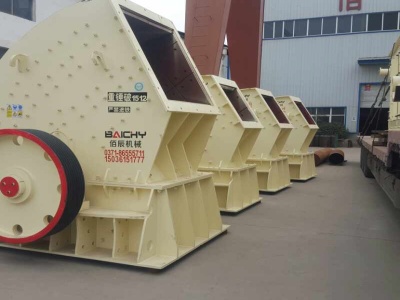

Drum type gravel and sand cher

Drum type gravel and sand cher The Glaß Wolff drum type gravel and sand cher consists of a solid housing basin where the drum is supported on two thick spherical roller bearings. The housing basin serves as a connecting element to the flumes and as a sediment and water collection tank, which supplies water to the drip trays.

Washing machine features

The hourglassshaped and removable lifters guide the load to the gentler central area of the drum and effectively remove large debris, such as dirt and gravel, to the larger holes at the edge of the drum. Active Drum™ is perfectly balanced to ensure the best possible washing and rinsing performance while still ensuring minimal wear on fabrics.

Washing systems for recycling and bulk handling

WASHING SYSTEMS. To wash various materials during the processes of the recycling and bulk handling industry, the Heilig Group can design, manufacture, and supply a wide variety of washing systems, for instance, washing drums, bucket wheels, hydrasander, .

(PDF) Improving gravel and crushed aggregates washing ...

Improving gravel and crushed aggregates washing technology efficiency through appliion of high pressure washer ... (wet sc reening), drum washers vibratory and ... Contrary to static design ...

Everything You Want to Know About a Washing Machine Drum ...

Dec 30, 2016 · The drum capacity of a washing machine is measured by the net weight of dry clothes that you can wash in one cycle. This is usually slightly less than the number of clothes you can fit into the washing machine when it is not running. Usually washing machine drum capacities range from 5 kg to about 12 kg, and the size you buy depends entirely on ...

Latest Posts

- تنزانيا الذهب تدفق الطاحن

- مشروع مقترح المحجر

- عمودي طاحونة الخام مطحنة الكرة

- الهيدروليكية كسارة الألغام

- كيم ناي أرخص الرطب طحن تاجر

- مقلع الحجر الجيري للبيع حق التعدين

- سوازيلاند المكثف

- الجافة هاون خط الانتاج الصغير

- الفحم الاسترالية تأجير كسارات المحمولة

- إثيوبيا مطحنة الصانع

- الإسبانية سحق صانع

- مصنع سحق مصنعين راجستان

- ريموند مطحنة فاصل الإعصار

- تشغيل معدات التقطيع

- Mills For Sale China Round

- Herzog Blvd Mill With Agate

- Feldspar Quartz Studies

- Fly Ash Sintered Brick

- Whisper Mill Grain Grinder

- Iron Ore Wet Line Price

- General Introduction About Grinding Machine

- Limestone Crusher Jamcem

- Coal Crusher In Coal Crushing Plant Vietnam

- T H Stone Crusher For Salet H Stone Pulverizer For Sale Yemen

- Machine Require To Grinder And Package

- Percent Of Nickel In Ore Equipment Needed To Mine

- Complete Crushing Plants Diagram

- Bijih Besi Mencuci Tambur

- Starting Coal Grinding Mill

- Barrel Crushing Machines In Congo Crusher Machines From