Coal Powder Handling

Minimum Ignition Energy

coal 40 1 coal, pittsburg 250 3 cocoa 100 1 cocoa 100180 3 coffee 160 3 copal 30 1 cork powder 45 1 cork powder 35100 3 corn meal 40 1 corn flour 20 1 corn starch 3060 3 cotton (filler) 25 1 cotton linters 1920 3 cyclohexane 1 cyclopentane 1 cyclopentane 3 1,3cyclopentadiene 1 cyclopropane 1

Coal Users' Group

The Coal Users' Group (formerly the PRB Coal Users' Group) is a worldwide organization focusing on sharing better practices promoting safe, efficient, and responsible use of coal. Contact Us: Secretary, Board of Directors, 4294 Martha Court, Newburgh, Indiana, USA, 47630. Email Us>> rdtaylor8880 / rdtaylor8880

Coal dust

Coal dust is a fine powdered form of which is created by the crushing, grinding, or pulverizing of coal. Because of the brittle nature of coal, coal dust can be created during mining, transportation, or by mechanically handling is a form of fugitive dust.. Grinding coal to dust before combusting it improves the speed and efficiency of burning and makes the coal easier to handle.

(PDF) Performance optimization of 1800MT capacity stacker ...

Performance optimization of 1800MT capacity stacker Reclaimer in coal handling plant in 600MW/660MW sub/super critical units. SN Dubey. Narendra N Dalei. Download PDF. Download Full PDF Package. This paper. A short summary of this paper. 17 Full PDFs related to this paper. Read Paper. Performance optimization of 1800MT capacity stacker Reclaimer in coal handling plant in .

USA

A system for the safe handling of pulverized coal, which system includes conventional coal pulverizing and drying equipment, with cyclones and bag filters added, the latter serving to separate the fine coal from the conveying gas (usually air); and explosion suppression and fire suppression systems, both of which latter systems include conventional components.

Coal Handling Plant Layout

· Various Stages in Coal Handling. The various stages in coal handling are : 1. Coal Delivery . From the supply points, the coal may be delivered to the power station through rail, road, river or sea. Plants situated near the river or sea may make use of ships or boats. The stations which cannot make use of ships or boats may be supplied either ...

Material Handling Systems | Coal and Ash handling systems ...

PC firing utilizes coal ground to a very fine powder sprayed into the furnace for combustion. CFB uses coal crushed to sizes of around 3 to 6 mm. The time energy and facility required to crush coal is much lesser than pulverizing coal. PC firing uses around 30 % of the combustion air as high pressure primary air for drying and transporting fuel. CFB uses higher pressure primary air which is 60 ...

Level Measurement Solutions for Coal Handling Appliions ...

· The coal powder is typically blown from the pulverizer into the boiler furnace. An RF point level switch is mounted in the top of the mill to indie a high level of coal. A highlevel indiion ...

Planning For Coal Mine Closures In the Powder River Basin ...

· Planning For Coal Mine Closures In the Powder River Basin. Author: Dan Cohn. ( ) on May 11, 2021 at 8:27 am. The past decade has seen a dramatic reversal of fortunes for the country's largest coal basin, the Powder River Basin of Wyoming and Montana. After hitting a highwater mark for coal production in 2010, the basin's output shrank by ...

Pneumatic Conveying of Fine Coal

· Pneumatic Conveying Consulting Services. You can use dilute phase conveying but to prevent dust explosion hazards, design this system as a closed loop conveying system with an inert conveying gas and maintain oxygen below 17% by weight. Also, follow NFPA standards 68, 69 and 650 for the detailed design.

Power plant engineering Unit

Coal, Ash and Dust Handling System Faculty: Page 1 of 24 COAL HANDLING SYSTEMS Due to continuously increasing demand for power at lower cost, it has become necessary to set up higher capacity thermal power stations. Rise in capacity of these plants pose problems in coal supply system from the coal mines to the power station and then during its internal handling. The .

Powder River Basin

· The Powder River Basin (PRB) is a region in southeast Montana and northeast Wyoming about 120 miles east to west and 200 miles north to south known for its coal deposits. It is the single largest source of coal mined in the United States and contains one of the largest deposits of coal in the world. Most of the active coal mining in the Powder River Basin actually takes place in drainages of ...

Coal degradation

The presence of fines ( mm) with the lump coal had a cushioning effect, which reduced the coal degradation during handling. Three different impact surfaces were tested to measure the ...

Level Measurement Solutions for Coal Handling Appliions ...

· · The coal powder is typically blown from the pulverizer into the boiler furnace. An RF point level switch is mounted in the top of the mill .

Coal Dust Suppression

Retards the oxidation and weathering of low rank coals, such as Powder River Basin (PRB) coals; Significantly reduces hot spots, smokers and spontaneous combustion at generating stations and coal terminals; Reduces BTU or calorific losses during storage at coal yards and terminals ; Foaming Agents DusTreat* Foaming Agents. The DusTreat foaming agents are formulated to produce resilient, low ...

COAL HANDLING PLANT

Coal inside the boiler should be completely in powder form so as to easily combustible. CHP (Coal handling plant) is a plant which handles the coal from its receipt to transporting it to boiler and store in bunker. It also processes the raw coal to make it suitable for boiler operation. 4. Coal It's Constituents Coal is a type of fuel which is non renewable in nature. It consists of high ...

Latest Posts

- تصميم كسارة البطيخ

- حرفة البناء الجزء الأول من المحجر التعليمي

- كسارة القمامة

- كيفية سحق الأسفلت

- ذروة كامل سحق الرمال

- مطحنة الأسمنت قدرة آلة حاسبة

- الجوال جهاز الدائرة المغلقة سحق

- كسارة الفك المعدات المستخدمة عادة في الهند

- منجم محطم البيانات التقنية

- الأبحاث المتعلقة ب جنوب أفريقيا تستخدم كسارات الفك

- معدات الطحن الأسفلت القديم

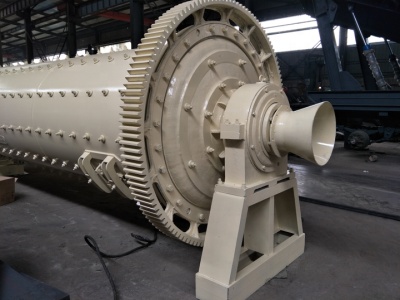

- المواصفات الميكانيكية مطحنة الكرة

- الميكانيكية آلة طحن الجبس

- ملموسة باستخدام الرمل الاصطناعي

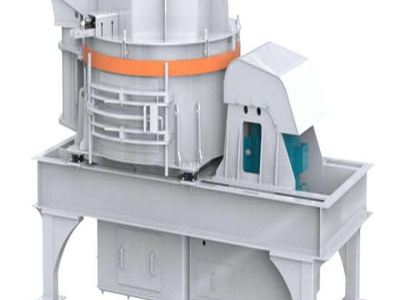

- Vertical Grinding Mill Specific Power

- Grinding Oudoor Concrete Los Angeles

- Lippmannportable Impact Crusher Reviews

- Box Bushing For Crusher

- Benefits Of Mobile Crusher Price Benefits Of Mobile Crusher

- Project Report On Stone Concrete In Marshall Islands

- Youtube Wet Copper Seperation

- Bed Mill Machine 2 3 M Italy

- Filling Area Calculation Ball Mill

- Stone Jaw Crusher Zenith 200 Tph Stone Crusher Machine

- Die Cast Underground Coal Mining Machines

- Mining Machinery Cost In Slovenia Stone Crusher Machine

- Automatic Stone Crusher In Congo 2019

- Size Of Raw Talc For Grinding Grinding Mill

- Used Stone Crushing Plant For Sale Stone Crushing Line

- Agarwala Stone Crusher Pakur