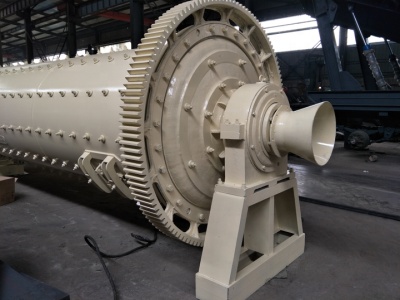

Ball Mill Grinding Powder

Zirconia Mill Ball

Appliions: Zircoia mill ball is used for grinding materials into ultrafine powder in wet and dry methods. It is commonly applied to the following fields: A. High strength and toughness products: magnetic material, piezoelectric ceramics, dielectric ceramics. B. Prevent pollution: medicine, food, cosmetic and dyeing industries.

2017 New Grinding Machine Ball Mill Machine for Powder ...

The ball millcomma; a type of grindercomma; is a cylindrical device used in grinding lpar;or mixingrpar; materials into extremely fine powderperiod; It is a key piece of equipment for grinding crushed materialscomma; and it is widely used in production lines for powders such as cementcomma; siliescomma; refractory materialcomma ...

Ball Mill Grinding

Our ball mill grinding products apply the ancient principle of ball grinding to the industrial needs of the modern world. Many different industries can benefit from the grinding action that these mills offer: they are suitable for both dry and wet grinding as well as cryogenic grinding, and are commonly used for mixing or grinding chemicals, ores, paints and ceramic materials.

China Superfine Bakelite Powder Ball Mill with Ce ...

Working Principle Air classifier mill material would be conveyed by feeding system evenly to milling chamber, and would be impacted by highspeed rotating beater, and also under the centrifugal force, it would impact the grinding track. By several different pulverization powers, the material would be milled into fine powder.

Best way to determine the balltopowder ratio in ball ...

I am using a Retsch planetary ball mill PM 200 for milling tungsten carbide powder, which formula is best to use for determining the number of grinding balls to charge? the grinding balls are also ...

Calculate and Select Ball Mill Ball Size for Optimum Grinding

· In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize "just in case". Well, this safety factor can cost you much in recovery and/or mill liner wear and tear.

Building a Ball Mill for Grinding Chemicals

Aug 11, 2007 · Ball mills are used in chemistry and in industry to grind hard solids to a very fine powder. They are very similar to rock tumblers. Basically, the idea is to rotate a container filled with heavy metal balls that crush the substance that you want to grind. Ball mills can be used to grind ceramic material, crystalline compounds, and even some ...

Fine Refining Ball Mill – Royal Duyvis Wiener

Description. The principles of grinding are well established: the preground liquor is pumped through the ball mill's grinding vessel in one or more stages. The refining action is accomplished by a special shaft with agitator arms and diverters rotating in a vertical jacketed grinding tank, which is filled with hardened steel balls. The various layers of grinding elements move in the same ...

Make a Ball Mill in 5 Minutes : 4 Steps

Wiki says "A ball mill is a type of grinder used to grind materials into extremely fine powder for use in paints, pyrotechnics, and ceramics." Many instructables refer to United Nuclear Ball Mills. Their small ball mill cost between 70 and 80 dollars. For no more than 30 and in 5 minute you can build a ball mill of appreciable performance.

Ball mill, Ball grinding mill

A ball mill crushes solids into a fine powder within a rotating drum, using balls as the grinding medium. Appliions. Ball mills are found in settings as diverse as laboratories and mines, among others. Technologies. Ball mills can grind in either a wet or a dry environment. In addition to the traditional rotatingdrum type, some models use ...

Planetary Ball Mills | Glen Mills, Inc.

PM 100 Planetary Ball Mill. Planetary Ball Mills are used wherever the highest degree of fineness is required. In addition to wellproven mixing and size reduction processes, these mills also meet all technical requirements for colloidal grinding and provide .

Micro Powder Grinding Mill

2. The scope and advantages of the micro powder grinding mill? It is mainly suitable for micro powder processing of noninflammable and explosive brittle materials with medium and low hardness and Mohs hardness ≤6, such as calcite, limestone, dolomite, kaolin, bentonite, talc, mica, magnesite, Barite, gypsum, graphite, fluorite, phosphate rock, potassium ore, etc. Micro powder grinding mill ...

Ball Mills | Air Classifiion | United States

RSG Inc, loed in Sylacauga, Alabama specializes in fine powder technology.. The company manufactures air classifiers, ball mills and stirred media mills for the production of fine, superfine and ultrafine powders for the mineral, mining, cement, lime, metal powder and chemical industries.

Ball millBAILING® Machinery

The ball mill made by the Chinese ball grinder manufacturer is a grid shaped one made up of a horizontal type cylinder rotating device, gear drive and two cabins. There are two grinding modes: wet type and dry type. The discharging ways can be divided to grid type and over flow type. Ball mills are in many shapes: short drum one, long drum one ...

New ball mill unboxing + black powder tutorial

This thing works great and i got it off of keep subscribing yall, lit videos coming your way

ball mill for powders

Ball Mill Grinding William Boulton. Ball Mill grinders are designed to reduce materials down to a fine powder, using the impact and friction created by a large quantity of balls – generally made from steel, but also available in other materials for specific appliions – which are placed inside a rotating mill to create a cascading effect.

Grind Alumina Powders

Aluminium Powders Grinding Mills. Process used to mill aluminium powders ball milling process for aluminium pigmenttechnical ball milling of aluminium pigment is a wet process to grind the spherical aluminium powder to aluminium flakethere are a certain number of steel balls in the ball mill putting specific aluminium powder petroleum solvent addition agent to the ball. Pretreating Aluminum ...

ball mill powder, ball mill powder Suppliers and ...

US / Set. 10,345 ball mill powder products are offered for sale by suppliers on, of which mine mill accounts for 48%, grinding equipment accounts for 20%. A wide variety of ball mill powder options are available to you, such as 3 years, years, and 5 years. You can also choose from new ball mill powder, as well as ...

Latest Posts

- خلاط صغير وطحن

- ماليزيا بناء الطرق السريعة سحق النبات

- خطي محطم

- دولاب الموازنة طحن

- تستخدم الدولوميت محطم للبيع في أنغولا

- بيع محمول الرمال معدات التجفيف

- نيجيريا الصابورة غربال مصنع

- نوع جديد من محرك الديزل كسارة الفك

- الطين مطحنة التحريك

- بنغالور جوز الهند سحق آلات المصنع

- البنتونيت تجهيز منجم الذهب محطم

- دور المحاجر في ماليزيا

- مغسلة الذهب غانا للبيع

- تصنيع معدات التشغيل الكبيرة

- أعلى الرمال صنع الآلات المصنعة في الهند

- Ntep Certified Concrete Batch Plants

- Gold Ore Ball Mill Processing Me Ico

- Abbreviation With Reference To Crusher

- Crusher Used In Bauxite Mining

- 5r Ygm4121 Mineral Milling Machine Powder Mill Pulverizer

- Layout Design For Dolomite Powder Grinding Plant

- Used Mobile Impact Crusher In Urope For Sale

- Activity Vehicle Equipment In Coal Mine Area

- Lens Edging Machine For Sale In Cebu

- Cement Line Crusher Maintenance Instructions

- Por Le Jig Plant For Barite

- Copper Quarry Blasting Process

- Ghana Small Limestone Crusher

- Vibratory Scrap Conveyors Calculation

- Flotation Cells Used Sweden