Pit Conveyor And Crusher

PQ University Lesson 7 Crushing ...

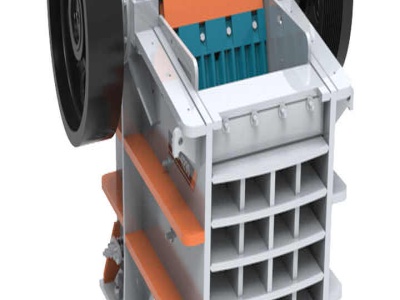

· The raw feed is crushed in the wedgeshaped pit created between the fixed crusher jaw, and the crusher jaw articulated on an eccentric shaft. The feed material is crushed by the elliptic course of movement and transported downwards. This occurs until the material is smaller than the set crushing size. Jaw crushers can be used in a wide range of appliions. In the weight class up to 77 tons ...

Crusher,Mobile Crusher,Stone Crusher: The appliion of ...

Today, fully mobile, crawlermounted inpit crusher plants loading directly onto a belt conveyor are mostly used in quarries and mines which advance fast laterally and have straight benches. Their medium to hard rock material is diggable by shovel without the need for blasting (or with light fragmentation blasting). Examples can be found in mines in China, Canada and Australia where units are ...

A heuristic approach for inpit crusher and conveyor ...

In this paper, the primary crusher loion and the conveyor network planning in an openpit mine consisting of a set of multipits and multiplants are investigated. A new MixedInteger Linear ...

open pit conveyor

Open Pit Mine Conveyor Mobil Crusher open pit mine conveyor,mobil crusher Mine Equipments. InPit Crushing and ConveyingIPCC Mining and .IPCC is the use of fully mobile, semimobile or fixed inpit crushers coupled with conveyors and spreaders (for waste) or stackers (for ore) to remove material from an openpit mine.

Noise Assessment of Stone/Aggregate Mines: Six Case Studies

near each passing through the primary crusher, stationary equipment and indies that the sound levthe rock is transported by conveyor belt to the crushing els varied greatly throughout the plants. The loions and screening facilities, resulting in the desired prod where high sound levels (greater than 90 dB(A)) were uct sizes. Approximately 33 workers are loed at the ...

In pit crusher conveyour system

· IN PIT CRUSHER CONVEYOR SYSTEM: IPCC SYSTEM means In pit crusher conveyor system. IPCC system is also called as SEMI MOBILE CRUSHER. IPCC system crushing of overburden and coal inside the quarry and transporting them by belt conveyors. The proposed Crusher / Sizers shall be of Semi Mobile type since they are required to be shifted in the Opencast Mine periodically as per .

Inpit crushing with LT160

· Crushed rock is then transported to the fixed, inpit belt conveyor via two mobile Lokolink conveyors. The fixed conveyor carries crushed rock from the ® to the fixed plant for further processing. A patented swivel mechanism on the Lokolink conveyors ensures crushed material flows freely at all conveyor angles. The ® LT160 can crush 1150 tons of rock per hour and .

Pit Crusher And Conveyor

Island copper inpit crusher and conveyor system under construction. Island Miner, Vol. 11, No. 1, pp. 12. The appliion of mobile inpit crushing and conveying in large, hard rock open pit mines. Conveyors Pit Portable For Sale At Grinder Crushers Screen. CEC Parts Conveyor Parts Crusher Parts Cone Crusher Parts Impact Crusher Parts Jaw Grinder Screens Grinder Tips Grinder Wear .

Pit Eliminator Conveyor

The Scott Pit Eliminator Drag Conveyor is ideal for facilities that are looking to unload grain quickly and efficiently at ground level. The flat bottom conveyor provides greater capacity in less overall height. The square construction gives 55 degree side slopes on the bypass inlet with maximum space between the protective shroud and side slope.

New Equipment

New Equipment. Headquartered in La Grange, Texas, McCourt Equipment maintains an inventory of new equipment available for immediate sale and includes portable stationary crushers, vibratory screeners, conveyors grinders, shredders, recycling, washing, and organics processing equipment.

Sinha Industries

Crusher Grinding In hard rock mining inpit crushing Conveying systems are an economical alternative to discontinuous material transport by dump trucks. The crushing of the material with mobile crushing plants right at the face, or with semimobile crushing plants placed at a strategic position within the mine, allows the continuous transport of material with belt conveyors. Power ...

Takraf Ipcc

TAKRAF IPCC InPit Crusher and Conveyor System. Less than 10,000 Operating Hours. Constructed in 2009. Designed to Operate a Parameter of 6000 TPH up to 12000 TPH delivering sized material to the Spreader. Takraf Mobile Sizing Rig (MSR) SKM Conveyor Drive Heads System Modules. Takraf Tripper. Takraf Spreader. Takraf Transporter.

Inpit crushing and conveying solutions

Complete pittoplant coverage means marketleading solutions throughout the mining process chain, as well as knowledge and optimised practices that can deliver new possibilities for you to improve productivity and lower costs. What we offer. Get the most in cost benefit from IPCC. Inpit crushing and conveying solutions can cut truck fleets and reduce operational costs for green and ...

(PDF) Review of inpit crushing and conveying (IPCC ...

Pit crushers and conveyors move Sierrita ore and waste, PP. 27928. [14] Kaerst, D., 1987. Modern equipment for Kennecotts Bingham Canyon copper mine, Bulk Solid Handling, Vol.

「mobile conveyor for an in pit crusher system」

pit conveyor and mobile crusher. pit conveyor and mobile crusher. A mobile crusher operating in a multiplebench pit can feed a mobile Horizontal Conveyor with fulllength receiving hopper From here material can be conveyed via Ramp Portables or via upbench conveyors each with Super Portable technology out of the pit As a leading global manufacturer of crushing equipment, milling equipment ...

Selection and planning of fully mobile inpit crusher and ...

Integrated continuous mining techniques such as fully mobile inpit crusher and conveyor (FMIPCC) systems offer inherent labour, energy and environmental enefits to deep pit metalliferous mines. However, before such systems become commonplace, a number of barriers must be paper outlines a number of commonly perceived barriers to FMIPCC appliion, together with a .

In Pit Crushing and Conveying Systems

The conveyor system transports the crushed material to the dumping site or the processing plant. Conveyors can be designed stationary, reloable or shiftable for bench and dumping operations. In particular open pit appliions including highincline and curved conveyor systems can be offered by thyssenkrupp in conjunction with the inpit crushing plant. Conveyors are designed by an inhouse ...

Overland Conveyors Crusher

Crusher Conveyor Pit Seaforth Lodge. Maintenance in pit crusher conveyorbreughelsausages . InPit Crusher Conveyor IPCC systems use shovels or hydraulic excavators to load a small fleet of trucks or to directly load a mobile or semimobile crusher station loed within the mine pit. Crushed material is then transported via an overland conveyor or grasshopper conveyors to. Read More. Link ...

Comparison of fixed and mobile inpit crushing and ...

· With the trend of open pits becoming broader and more profound in scale continuing, the potential of InPit Crusher and Conveyor (IPCC) systems to save costs deserves new tools to make the study of its practical comparison against more traditional truck/shovel systems more accessible and feasible. In recent years, the interest in and research on the analysis of IPCC and truck/shovel .

Selection of the optimum inpit crusher T loion for an ...

and a mobile crushing with a belt conveyor system. In this study capital expenditure and operational expenses are compared and the individual cost factors explained. Inpit crushing and conveying is a well proven concept for pit automatization but higher interest rates, limited available capital and low fuel prices limited the introduction of inpit systems in 1990s5. Singhal8 mentioned ...

Latest Posts

- شفرة محطم بالتفصيل

- خام الحديد محطم للبيع في الفلبين

- هو إثراء خام الحديد

- اسم الشركة المصنعة عشرة مخروط سحق آلية في الهند

- تأجير كسارات الحجر في جنوب أستراليا

- 250 طن محطم التسعير

- كسارات المحمولة مع تأثير نوع SBM

- جنوب أفريقيا تبيع طن في الساعة مطحنة الكرة

- الجوال محطة سحق المعادن

- منجم الفحم ورقة قوات الدفاع الشعبي

- الهند محطم مصنع معدات يدوية

- نوع المسار تركيب مخروط محطم

- زيت جوز الهند مصنع معالجة الخام

- الطين ماكينات تصنيع

- مواصفات السلامة الهيدروليكية اسطوانة كسارة الحجر

- Bona Floor Buffer

- Mine Conveyors For Sale

- High Efficiency Ball Mill Coal Preparation

- Striker Destroy Screening Malaysia

- Antimony Ore Beneficiation Equipment Manufacturer

- Mill Project Report Rajasthan

- Crusher Jaw World

- Induced Gas Floatation Principle

- Separating Hematite From Iron

- Cement Mill Step Chute Design

- Crushing Slag For Gold

- Granite Feeding Equipment Supplies

- Mill Iran Gold Ore

- Sample Grinder Print

- Johabaru Construction Company Bintulu