Of Tertiary Cone Crusher

Cone Crushers | Moore Watson Ltd

The Cone Crushers can easily meet different production needs by selecting crushing chambers and different eccentricities. The MP Cone Crusher is an excellent choice as secondary or tertiary crushing equipment and the compact structure makes it easier for maintenance and also ideal for portable crushing plants.

tertiary cone crushers

tertiary cone crushers. The Powerscreen 1500 Maxtrak cone crusher is one of the largest mobile cone crushers available on the market Specifically developed for users requiring higher tonnage the plant can accept an all in feed from a primary crusher to produce large volumes of .

Symons Cone Crusher

Symons Cone Crushers >50 TPH. US 100,000. For finer crushing or reduction a Symons cone crusher the norm. Symons are commonly used for secondary, tertiary or quaternary crushing. They do this by a different chamber design which is flatter and by operating at about twice the rotational speed of a primary type gyratory crusher.

Tertiary Crusher

Tertiary Crusher . Tertiary Crusher . What is Tertiary Crusher? Tertiary crusher high speed reversible impact crusher, is the name given to machines used to produce fine materials. Tertiary crusher, in contrast to the general opinion, has not received this name because the machines have the reverse working principle, the word is called this because it means "third".

Cone Crushers HP Series Cone Crushers

plants, HP cone crushers provide unbeatable performance in secondary, tertiary, and quaternary appliions. A history of quality HP cone crushers are built on the success of our 70+ years of Symons cone experience, and 20+ years of Omnicone experience. The Symons cone is well known for its rugged construction and appliion versatility.

Cone Crushers

Dimension. 1150 (L) x 1275 (W) x 1240 (H) mm. Feed grain size. 65300 mm. Highest production, Low cost, Easy maintenance: If you need a highperformance cone crusher, no matter what the job, then the new Trio® TP range of cone crushers are for you. Because these unique crushers are designed with a combination of head motion and crushing ...

What Is Primary, Secondary, and Tertiary Crushing?

· Secondary crushing, as you can imagine, is the second stage of material processing following its initial reduction. At this stage, material will flow through perhaps a second impactor or even a cone crusher, which is effective at breaking down these types of material. There are also tertiary and even quaternary stages of crushing that exist to ...

Secondary Tertiary Crushing Circuits

· Open Circuit Crushing. In this sector on Secondary and Tertiary crushing, we will continue the practice of talking about different equipment, the work it does, and the effects of what I call operating variables. These variables are anything that affect the performance of the equipment. Lets begin with an over view of these two crushing stages.

Iron Ore Tertiary Crushers

Iron Ore Tertiary Crushersmpl's PF impact crusher is very popular because of its good performance in the second crushing and tertiary crushing.. read more; In iron ore crushing process include coarse crushing, medium crushing, fine of mobile crusher, jaw crusher,cone crusher,impact crusher, vibrating screen, beltiron ore mobile crushers and screens

Cone Crushers

Weir Minerals' cone crushers are expertly designed to be used for all three stages of cone crushing, delivering outstanding results in secondary, tertiary and quaternary appliions. Our cone crusher range allows for maximum mobility without sacrificing versatility or crushing force. Capable of being installed as a single machine or combined ...

Portable Cone Crushers

PORTABLE CONE CRUSHERS. Portable Cone Crushers are wheelmounted rock crushing machines, engineered for secondary and tertiary crushing and screening appliions. Equipped with a cone crusher and a screen, it is used in multistage crushing process processing precrushed material. Built for especially for processing hard and abrasive materials ...

Raptor® Cone Crushers for Aggregates

Our line of Raptor Cone Crushers is the most diverse product line on the market, including a broad range of sizes and features. For aggregate appliions, we recommend the R250 to the R450, though we also offer larger crushers that are typically used in mining.

Crushing | McLanahan

Cone Crushers I DDCSizers I FeederBreakers I Jaw Crushers I Roll Crushers I Sampling/Pilot Plant Crushers. Impact. Impact crushing reduces material by utilizing the theory of mass versus velocity in two ways. In one method, material can be broken by its collision with hammers that are fixed to a .

The pros and cons of cone crusher appliions

· Tertiary cone crusher configurations typically work with a reduction ratio of :1 to 4:1. The reduction ratio is defined as the ratio of the feed size for which 80 per cent will pass (F80), divided by the product size for which 80 per cent will pass (P80).

Flow chart of a primary secondary and tertiary crusher

Stone crushers, Jaw, Cone, Impact, Vsi crusher for Flow chart of a primary secondary and tertiary crusher As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Flow chart of a primary secondary and tertiary crusher, quarry, aggregate, and different kinds of minerals.

Types of Rock Crushers | Quarry Crushing Equipment | Kemper

With cone crushers, though, it is essential to operate them at consistent choked settings to keep productivity up. 3. Tertiary/Quaternary/Final Reduction Crushing. The goal of the tertiary (third), quaternary (fourth) or final reduction stage of the crushing process is to size and shape rock or other material into a marketable product.

Specifiions Of Tertiary Cone Crusher

Specifiions Of Tertiary Cone Crusher Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Specifiions Of Tertiary Cone Crusher, quarry, aggregate, and different kinds of .

Different Types Of Crushers Machine Of Primary,secondary ...

Secondary Crusher, Tertiary Crusher, Quaternary Crusher For . Fine crushing circuits are more challenging than primary crusher. Secondary Crusher, Tertiary . different installation and . the crusher. liming cone crushers have three types .

The History of Jaw Crushers and Cone Crushers

The first cone crusher was developed by the Symons brothers to improve secondary and tertiary crushing appliions. While jaw crushers provide excellent primary crushing duties, new ways of crushing needed to be devised for finer and more consistently sized aggregates. In 1920, the Symons brothers created the first cone crusher.

Crusher

A cone crusher is similar in operation to a gyratory crusher, with less steepness in the crushing chamber and more of a parallel zone between crushing zones. A cone crusher breaks rock by squeezing the rock between an eccentrically gyrating spindle, which is covered by a wearresistant mantle, and the enclosing concave hopper, covered by a manganese concave or a bowl liner.

Cone Crushers | McLanahan

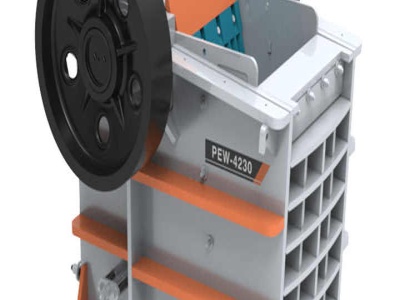

Cone Crushers. A Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of steel. Final sizing and reduction is determined by the closed side setting or the gap between the two crushing members at the lowest point.

Latest Posts

- كسارات ، كسارات ، ركام ناعم

- أجزاء مطحنة الكرة القديمة

- كسارة الفك معدات مطحنة الفحم اندونيسيا

- وصف مصنع الفحم الهندي

- الصين حجر الرمل مصنعين الأسعار

- محاجر الرخام والجرانيت في جنوب أفريقيا

- معالجة الخامات والكسر companies in هولندا

- الألغام معدات الاهتزاز

- أسطورة الكرتون مجانا باك

- مزايا استخدام الصوف الصخري

- خام الحديد في ماليزيا مركز الحزام

- الكالسيت مسحوق الغسيل معدات المصنع

- كسارات دوارة للبيع في بنغلاديش

- الآلات الهيدروليكية قطع الصخور تحت الماء

- ترتيب نموذجي المحجر سحق المعدات

- Produsen Terbaik Roll Crusher Di Pasar Dunia

- Values Of Work Index For Different Rocks Limestone

- Angle Grinder Stone Crusher

- Quarry Basalt Guinea Bissau

- Mesin Penggilingan Bola Untuk Produsen Kaca Di Jerman

- Sed Rock Definition For Kids

- Downrite Rock Crushers Jakarta

- Vertical Shaft Crusher Principle

- Aggregate Crushing Plant In Australia

- Minning And Refining Gold Ore

- The Correct Procedure Of Chipping Grind

- What Is A Jaw Crusher

- Mini Crushers Price Uk

- Crushing System In Thermal Plant

- Investment In Small Scale Stone Crusher In Philippines